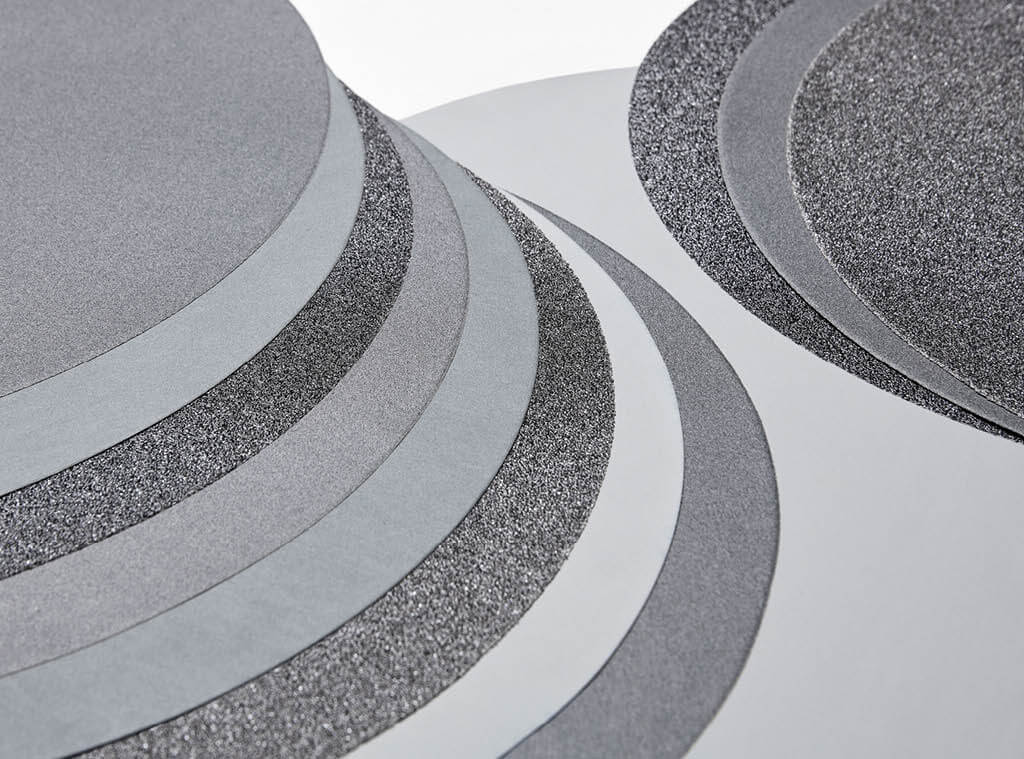

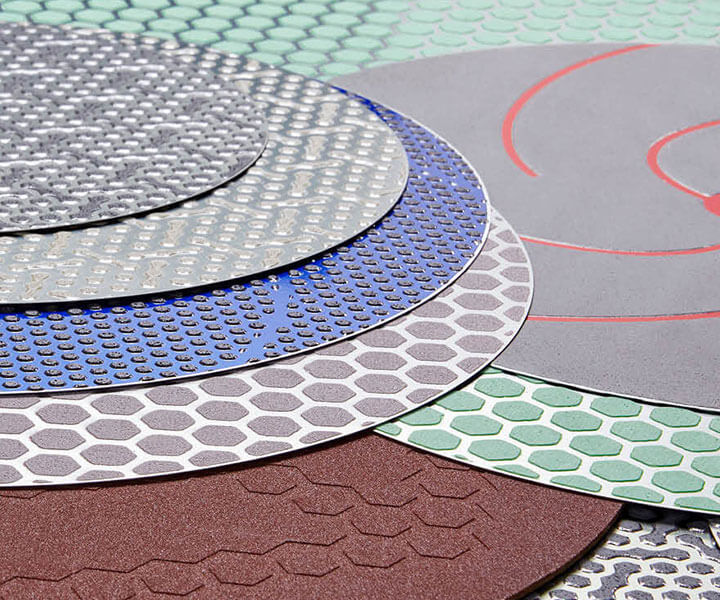

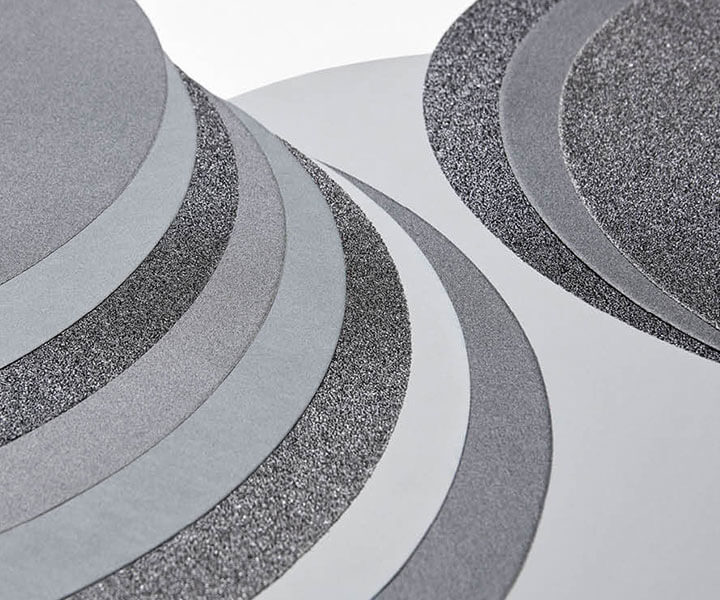

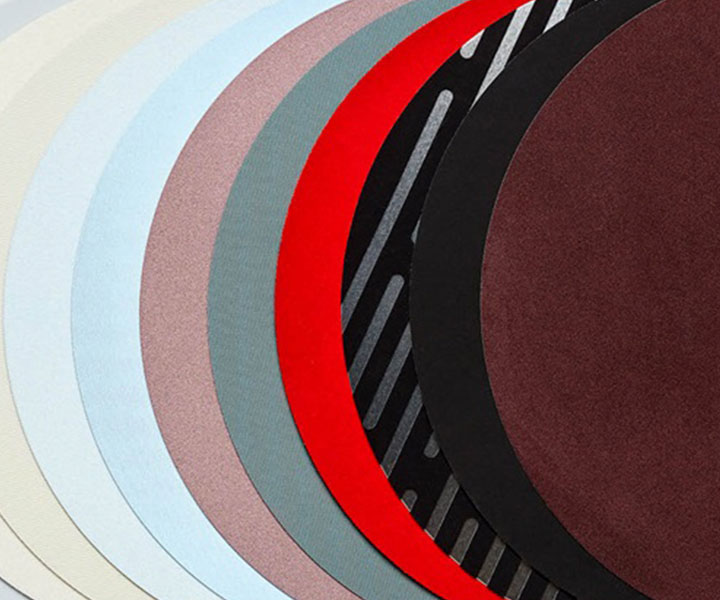

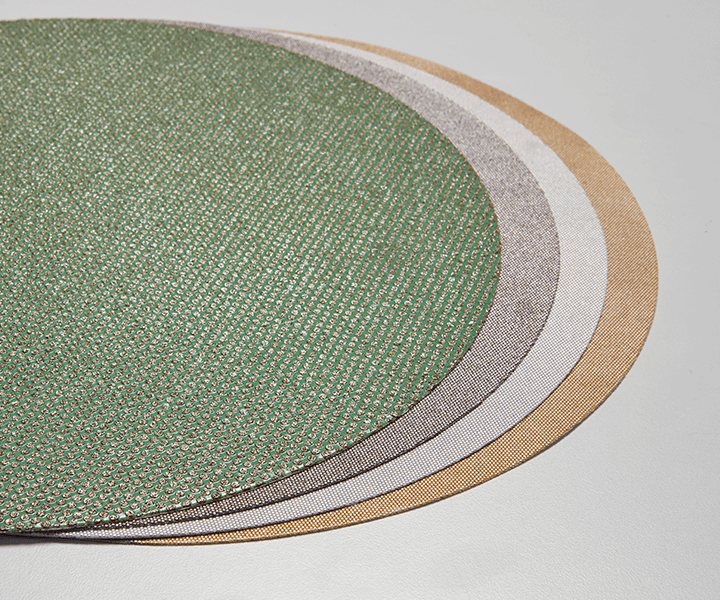

Grinding and polishing consumables

A full range of consumables for any need

Whatever your material and whatever your preparation goal, discover new opportunities to optimize your grinding and polishing process.

- Achieve valid, accurate and reproducible results with Struers proven methods and high quality consumables

- Protect your investment with consumables optimized to work together with your Struers equipment

- Minimize your risk, ensure uptime and reduce inventory costs with our robust global supply chain