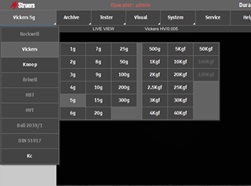

Model Types

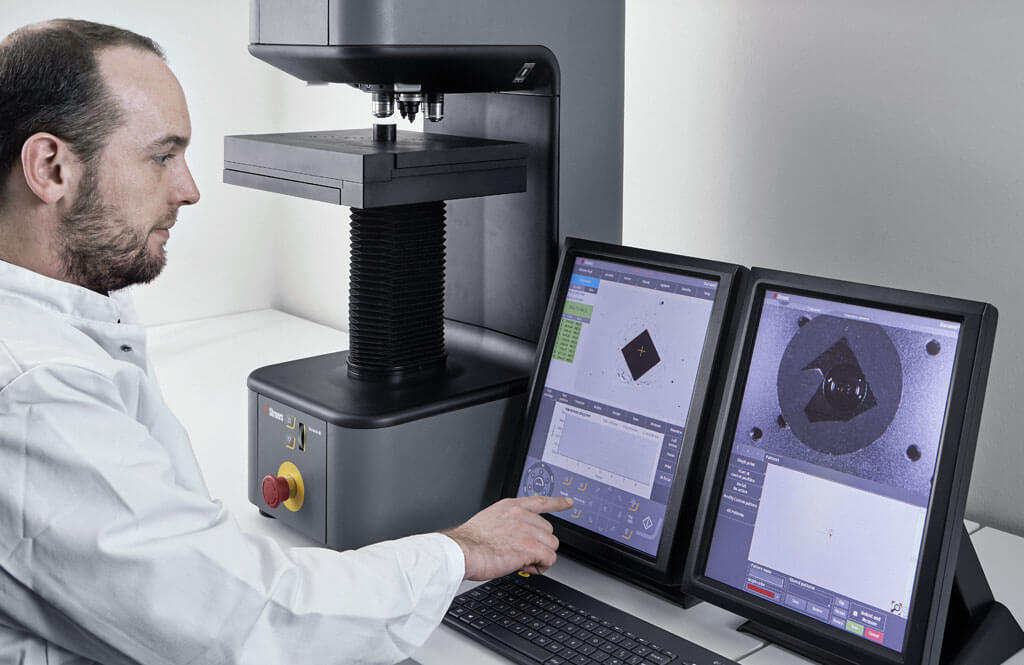

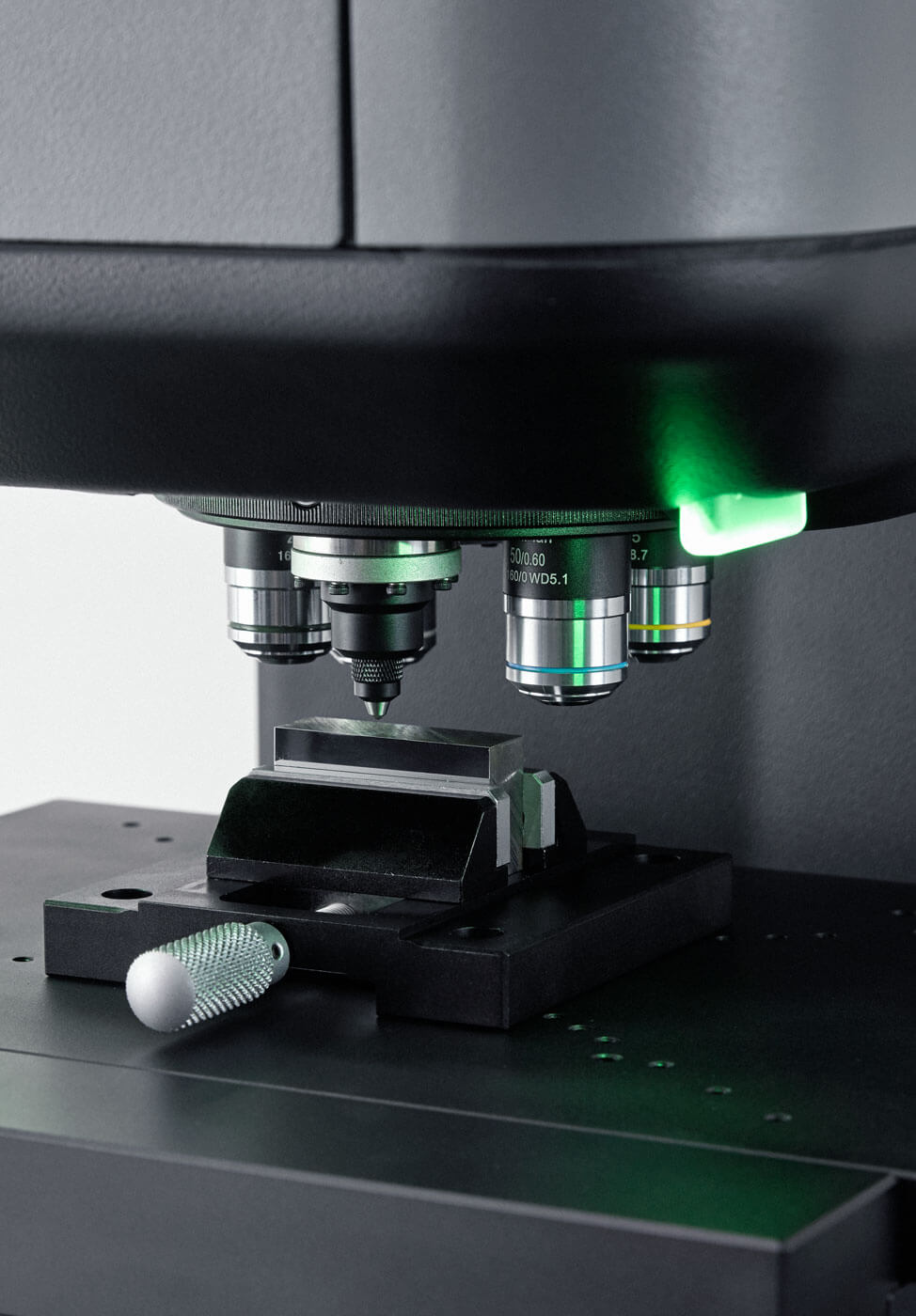

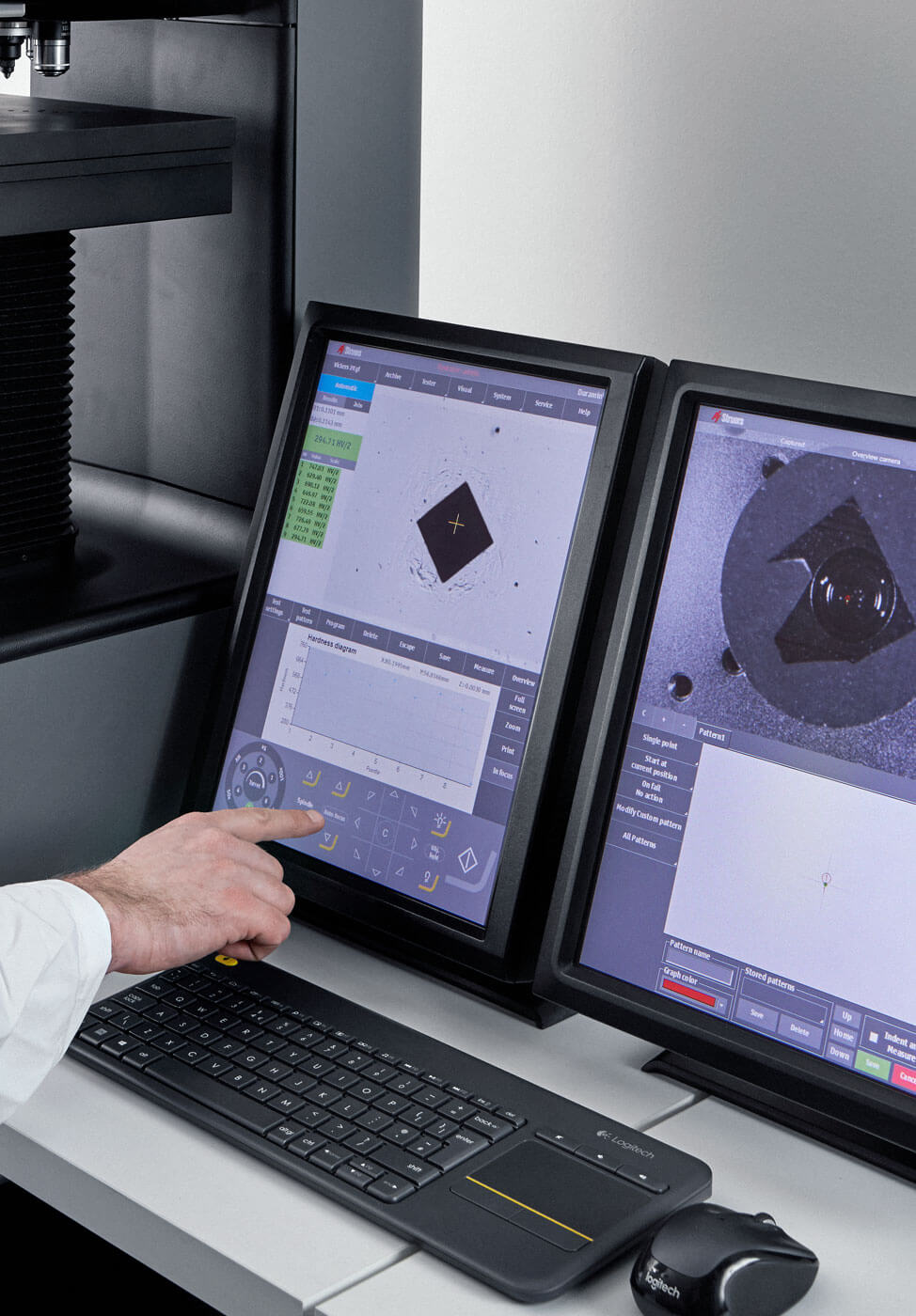

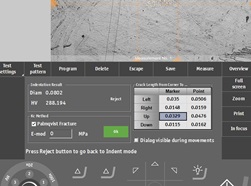

All testers within the Duramin-40 range come with motorized Z-axis, high-resolution camera, LED illumination, auto focus, and automatic image evaluation. All include an integrated PC with an eight-inch color touchscreen. Duramin-40 M comes with a manual XY-stage (size 90 x 90 mm, stroke 25 x 25 mm) including manual micrometers. The test height is 0-200 mm. It includes a motorized, six-position measurement turret. Duramin-40 A comes with a test point editor and motorized XY-stage (size 350 x 225 mm, stroke 220 x 120 mm). The test height is 0-200 mm. It includes an automatic, six-position measurement turret. Duramin-40 AC comes with a test point editor and motorized XY-stage (size 350 x 225 mm, stroke 220 x 120 mm). The test height is 0-200 mm. It includes an automatic, seven-position measurement turret, with an overview camera (FOV 200 x 160 mm) for easy test point positioning. Objective lenses and indenters are ordered separately.

Duramin-40 M1/A1/AC1

Low load hardness tester based on load cell technology for the automatic testing of Vickers, Knoop, and Brinell With an extended test load range of 0.098 – 98.1 N (10 gf – 10 kgf)

Duramin-40 M2/A2/AC2

Low load hardness tester based on load cell technology for the automatic testing of Vickers, Knoop, and Brinell With an extended test load range of 0.098 – 306.4 N (10 gf – 31.25 kgf)

Duramin-40 M3/A3/AC3

Low load hardness tester based on load cell technology for the automatic testing of Vickers, Knoop, and Brinell With an extended test load range of 0.0098 – 612.9 N (1.0 gf – 62.5 kgf).

| Variants |

10 gf – 10 kgf |

10 gf – 31.25 kgf |

1.0 gf – 62.5 kgf |

| Manual XY-stage |

Duramin-40 M1 |

Duramin-40 M2 |

Duramin-40 M3 |

| Automatic XY-stage |

Duramin-40 A1 |

Duramin-40 A2 |

Duramin-40 A3 |

| Automatic XY-stage + overview camera |

Duramin-40 AC1 |

Duramin-40 AC2 |

Duramin-40 AC3 |

Struers’ equipment is in conformity with the provisions of the applicable international directives and their appurtenant standards. Struers’ products are subject to constant product development. Therefore, we reserve the right to introduce changes to our products without notice.