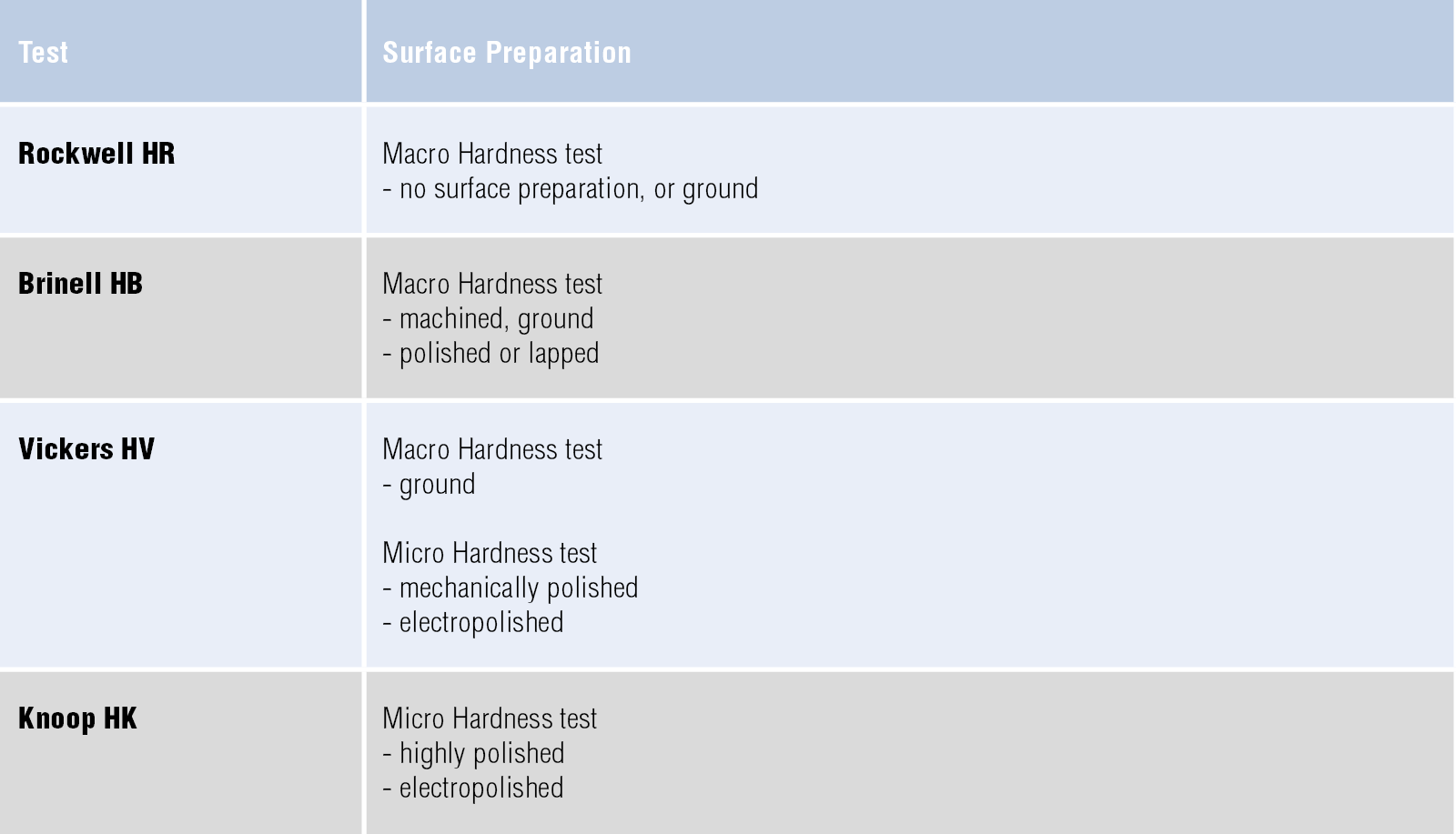

Surface preparation requirements for hardness testing

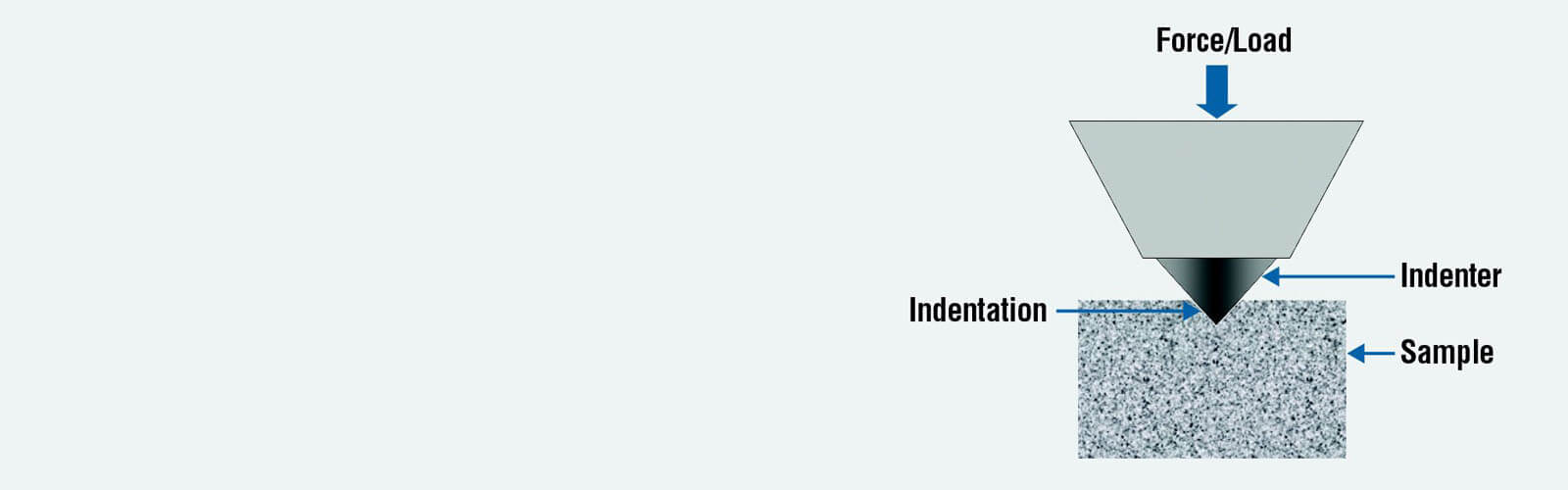

Before hardness testing of metallic materials or other materials, you must prepare the surface. The required surface condition depends on the type of test and load used. In general, the quality of surface preparation has a direct effect on the hardness test result, so you should consider the trade-off between surface quality and test result variation before deciding on an inferior surface preparation.

Macro hardness testing

A ground surface is usually sufficient, and sometimes no preparation is required.

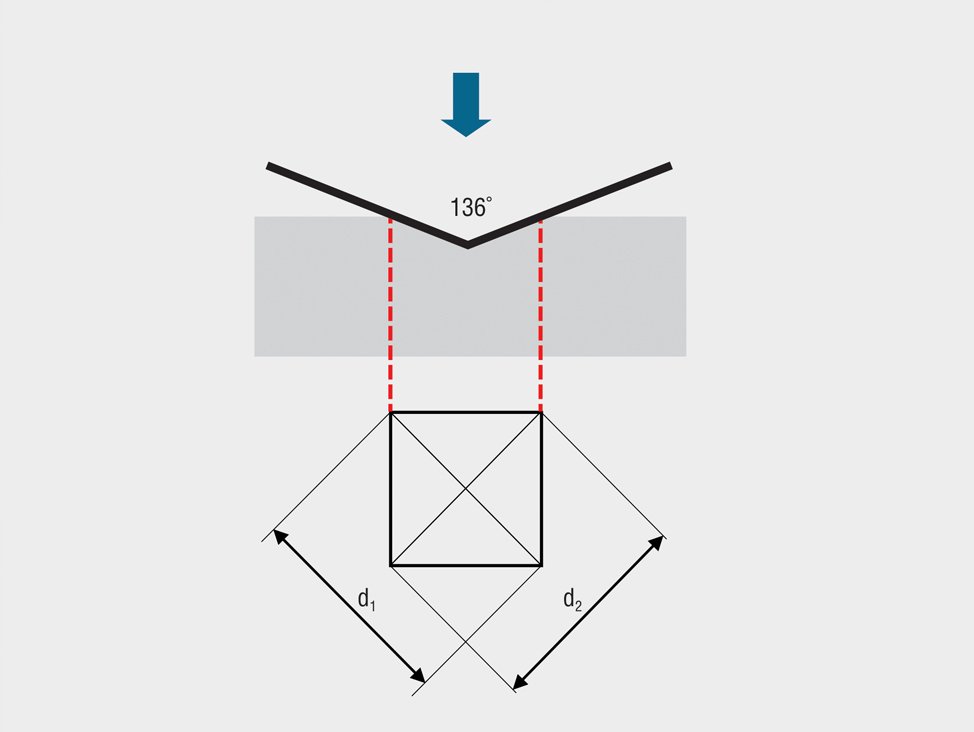

Micro hardness testing

Due to the lower loads used during hardness testing, micro hardness testing requires a polished or electropolished surface. It is important that the borders/corners of an optically evaluated impression are clearly visible. This can be performed mechanically, chemically, or electrochemically. It is important that heating or cold working does not change the surface properties of the specimen.

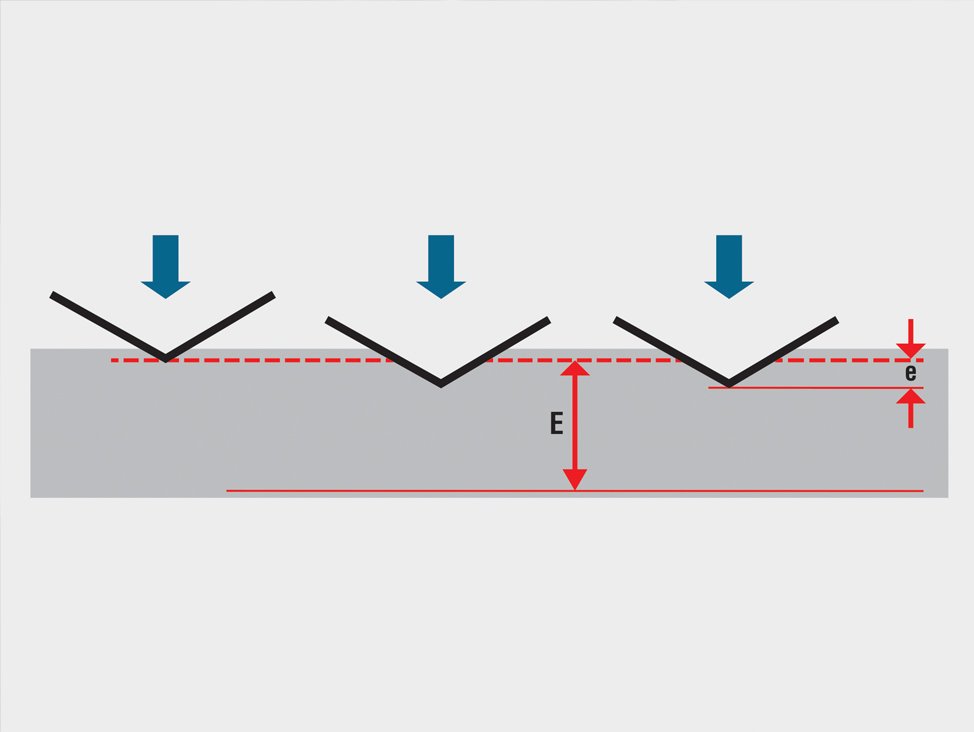

Deformations

Cutting and grinding may introduce deformations. These must be removed by polishing down to 6.0, 3.0, or 1.0 μm, depending on the hardness test load.

For small loads (less than 300 gf1) the surface needs to be completely free of deformations, and the specimens require oxide or electrolytic polishing to obtain a completely damage-free surface. You should also take into account that soft and/or ductile materials (i.e. for HV less than 120-150) are more sensitive when it comes to introducing preparation artefacts.

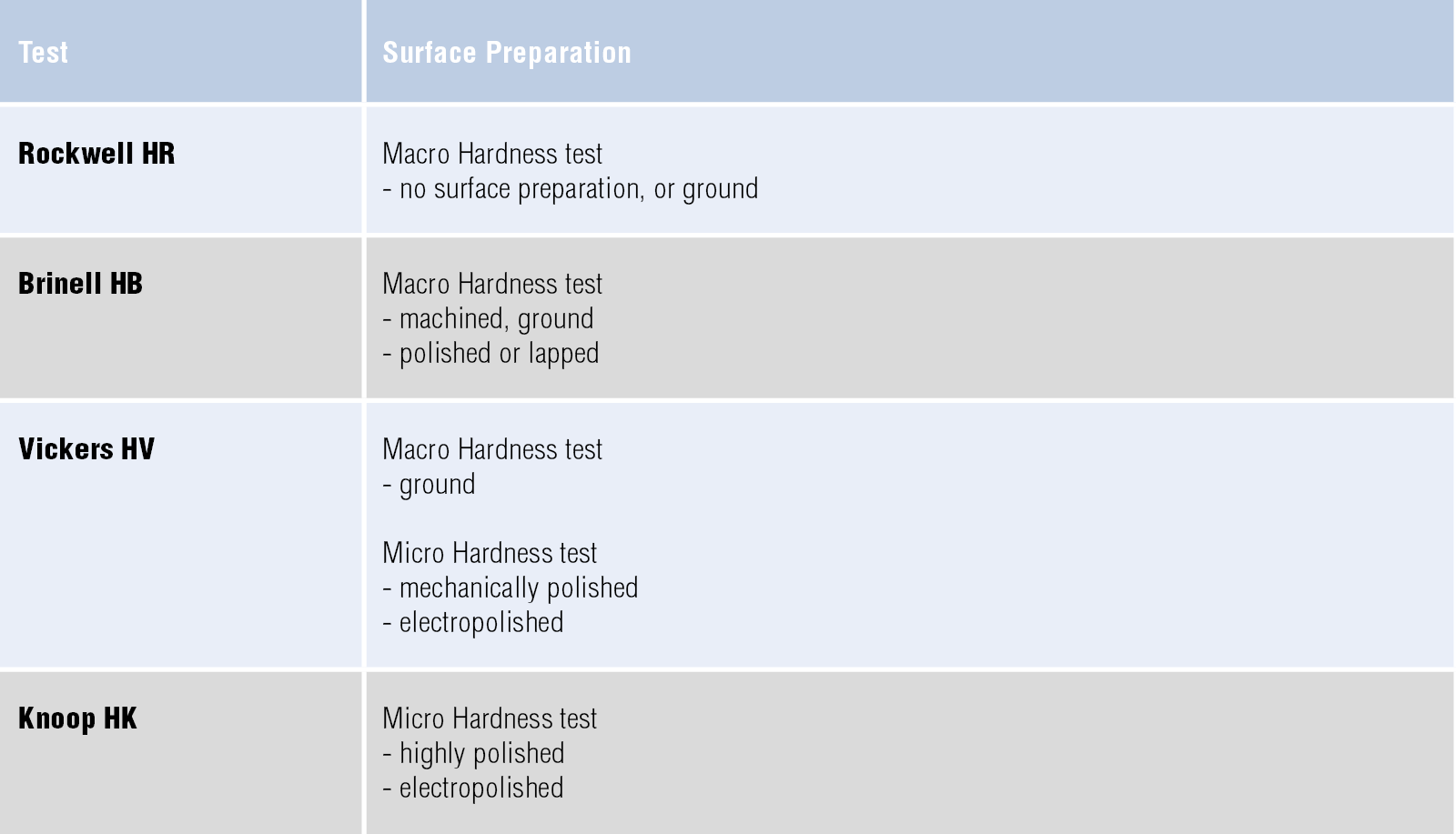

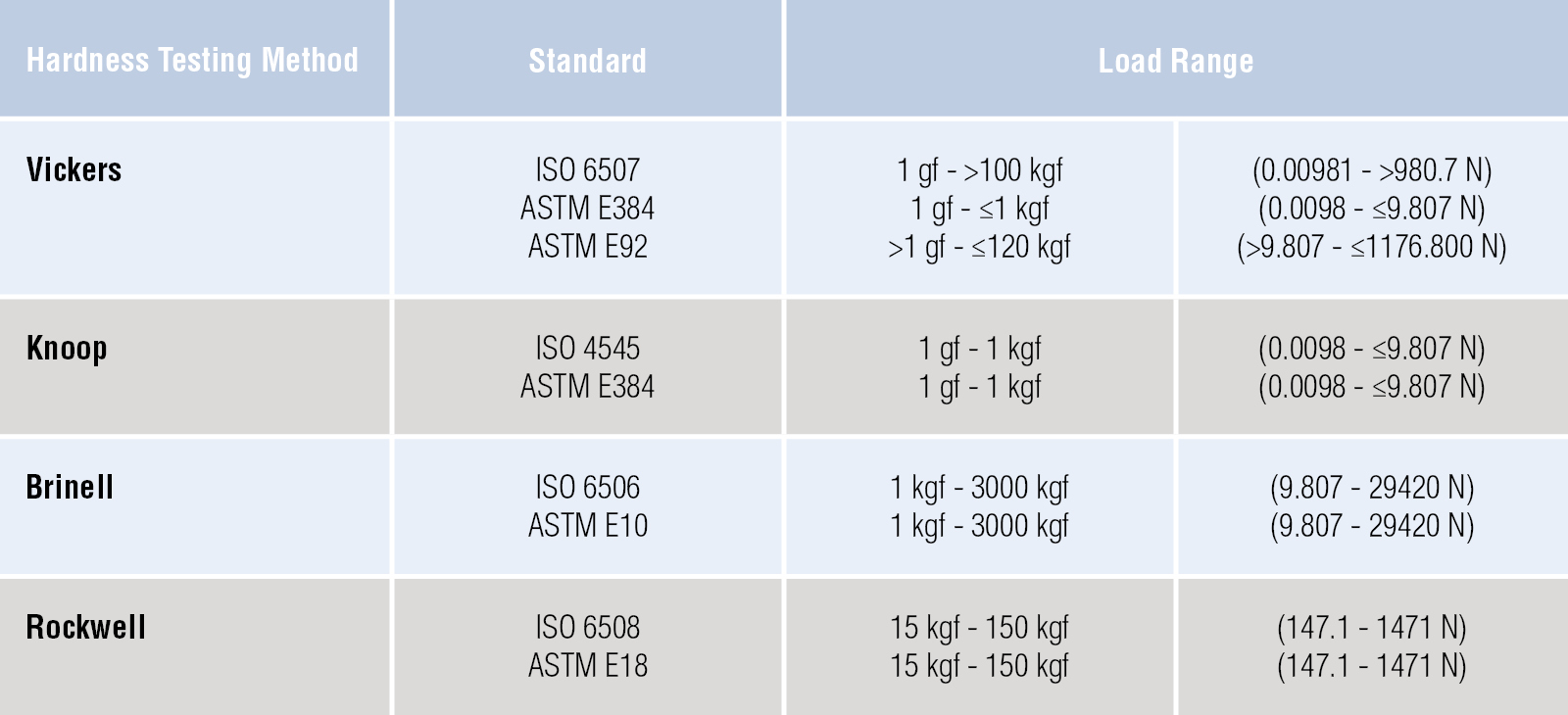

In the table below, you can see the surface preparation requirements for the different hardness tests.