STAY UPDATED: GET OUR NEWEST INSIGHTS IN MANUFACTURING

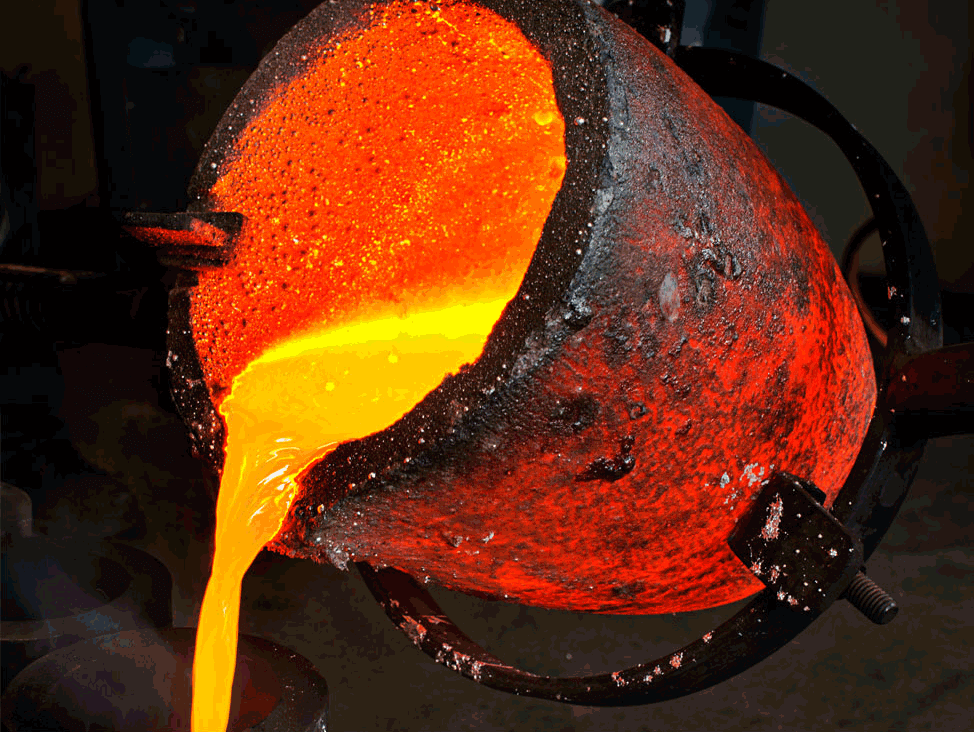

Struers was the first company in the world to market an automatic preparation machine as part of the materialographic process. More than 100 years later, we continue to develop equipment and consumables for specimen preparation, and for quality assurance in the mass production of steel and other metal products, ranging from structures such as buildings and bridges to car wheels and ball bearings. Struers employs process knowledge and the latest technologies in its materialographic preparation equipment to ensure repeatability, speed, and cost-efficiency of the metallurgy industry all over the world.