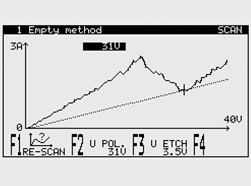

Automatic determination of parameters

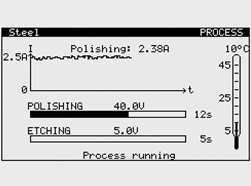

LectroPol-5 features a scanning function that helps to determine the correct voltage for both polishing and etching, thus saving time and avoiding human error. LectroPol-5 displays the scan curve, while the user selects and sets the voltage. Instead of time-consuming trial and error parameter testing, it is now easy to find the correct settings after a single scan of a new sample material.

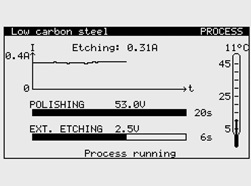

Method Database

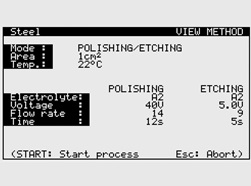

The LectroPol-5 comes with ten polishing/etching methods for various materials, enabling immediate preparation of a wide range of materials without any lengthy and time-consuming trials. These methods can also be used as starting points for the development of methods for other materials. The LectroPol-5 database can store 20 user-defined methods.

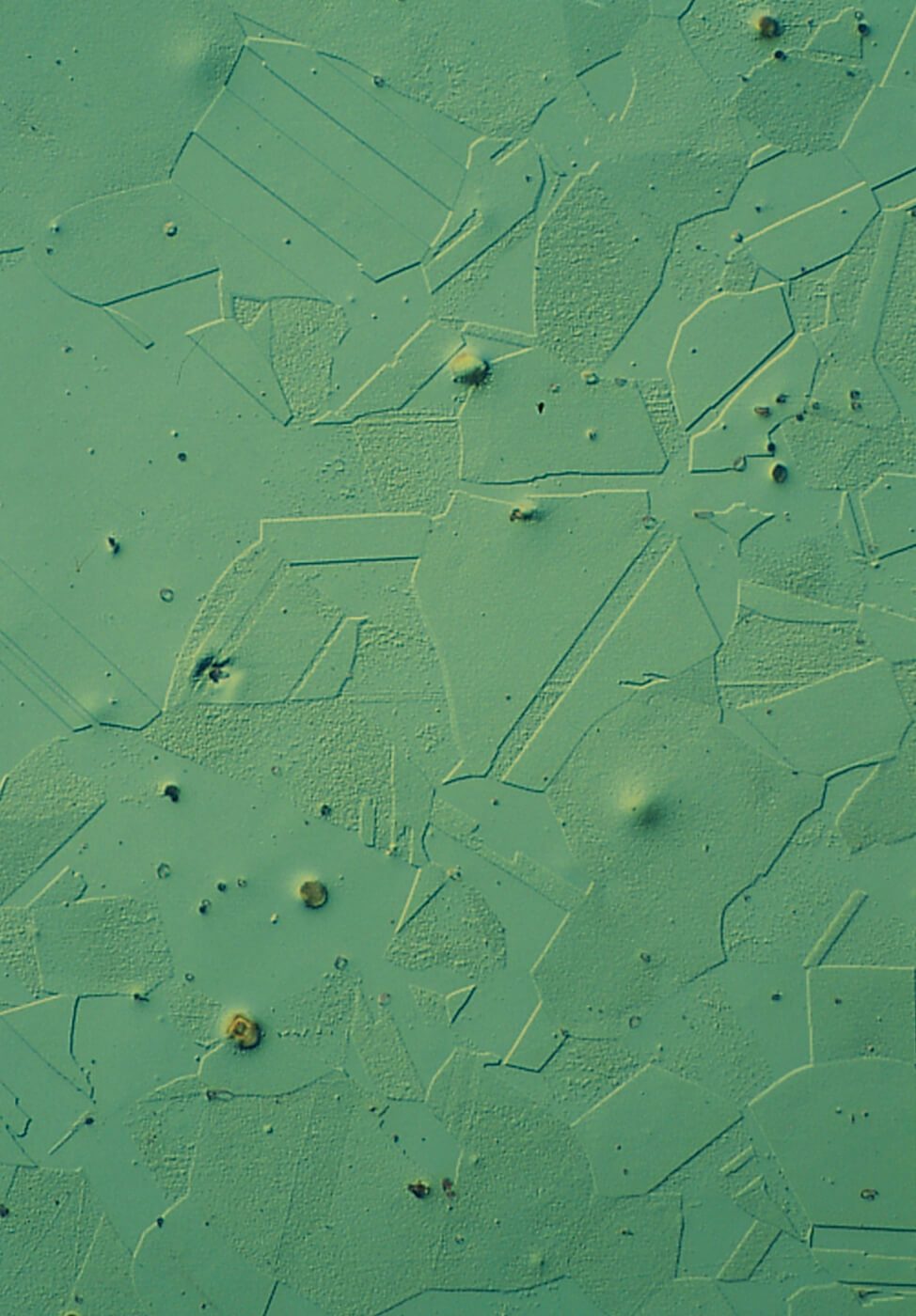

Short polishing times and high reproducibility

Electrolytic polishing and etching have very short preparation times when compared with normal mechanical specimen preparation. Microprocessor control and database functions ensure the use of correct parameters. LectroPol- 5 combines both short preparation times and high reproducibility and is thus the ideal choice for fast quality control requirements.