Tegramin facts

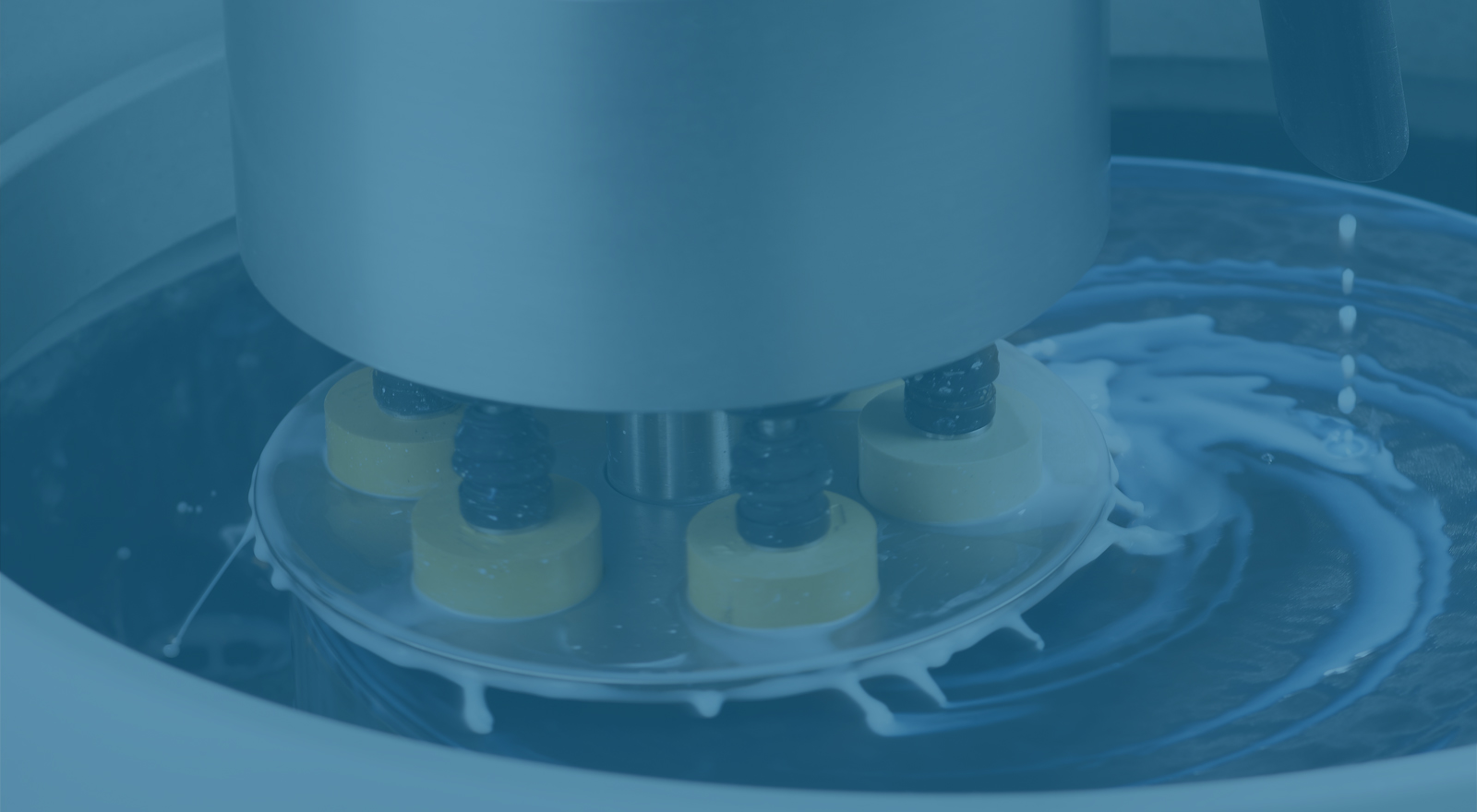

- Semi-automatic all-purpose grinding and polishing machine

- Advanced dosing functions for high reproducibility

- Fine-tune multiple features for higher efficiency across different tasks

- High reproducibility due to precise force control and dual column construction

- Full flexibility – prepare single or multiple specimens

- Built-in removal sensors increase process efficiency

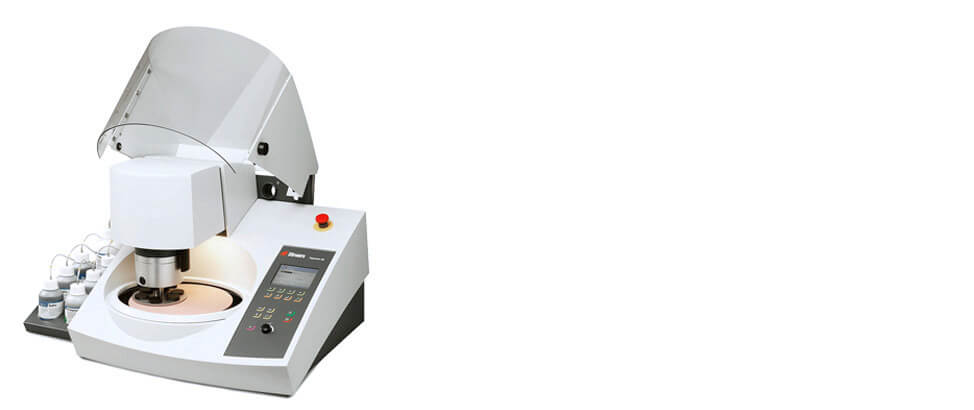

Tegramin’s compact design, integrated specimen mover, automated process control, and user-friendly operation make it a reliable, all-purpose grinding and polishing solution that delivers highly reproducible results and better process standardization. Extremely efficient, accurate, and versatile, it is ideal for labs that prepare different materials and need to adjust parameters often. Everything is designed to utilize the preparation surface area, making your consumables last longer.

Exceptional reproducibility

Tegramin features a sturdy and durable design to ensure the best possible preparation result. The dual column construction supports the specimen mover to ensure you prepare perfectly plane samples. At the same time, the aluminum base eliminates vibrations to help you achieve reproducible results.

Tegramin also helps to minimize contamination between steps with a special pump function that reverses slightly to retract the suspension and lubricant from the dosing nozzle when you move to a finer grinding or polishing step.

Advanced dosing functions

Precise dosing of diamond suspension and lubricant is an important factor for increasing the reproducibility of your preparation results. Tegramin features optional pumps with a calibration function to ensure constant dosing levels throughout the lifetime of the machine. This also helps ensure you know how much suspension is left in the bottle.

Greater control and efficiency

Tegramin has many special features you can adjust and fine-tune to match your exact preparation process. These include force as low as 5 N to help avoid damaging small or sensitive specimens. The force can be increased or decreased gradually while the speed of the preparation surface and mover plate ramps up or down, giving your precise control. At the same time, the start-stop control helps you to minimize any potential damage to the sample.

Tegramin also improves process efficiency by minimizing grinding time. It does this with a built-in sensor that ensures accurate material removal (in the range of 50-5,000 μm). It is also possible to change the direction of the specimen mover for optimal use with different materials and consumables.

Discover more

KEY FEATURES THAT ENABLE HIGH-QUALITY SPECIMEN PREPARATION

-

Rigid design for higher reproducibility

Tegramin has an exceptionally sturdy design to improve reproducibility, increase specimen planeness, and lower noise during preparation. The specimen mover is fixed on a solid construction with a massive cast aluminum base. The up/down movement is based on two strong columns, making the entire systems as solid as possible. This ensures the least possible vibration for higher sample accuracy and reproducibility.

Rigid design for higher reproducibility

-

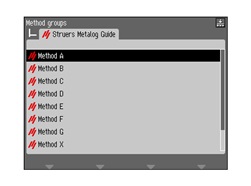

Method database for accurate preparation from day 1

Tegramin includes 10 Struers Metalog Guide methods, covering all major material groups. The methods have been developed for maximum performance on Tegramin and allow you to get started right away, with minimal learning time. The methods also provide an excellent starting point for developing your own methods. These can easily be stored in the database for fast and easy preparation.

Method database for accurate preparation from day 1

-

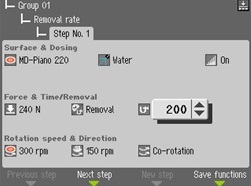

Advanced dosing for different preparation tasks

Tegramin can be used with three different dosing modules to cover a wide range of preparation tasks, depending on your needs.

• Module with one pump for DP-suspension or lubricant

• Module with two pumps for DP-suspensions or lubricants

• Module with two pumps for DP-suspensions or lubricants and one pump with a water connection for OP-suspension

The modules can be combined in various ways, giving you up to 7 pumps in total and many different combinations.Advanced dosing for different preparation tasks

-

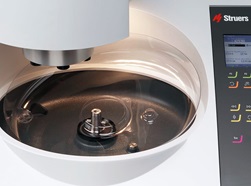

Bowl flush for fast and easy cleaning

To facilitate fast and easy cleaning, the Tegramin-30 and Tegramin-25 are equipped with a bowl flush function. When the function is activated, disc cooling occurs while the disc is rotating. Any water that is sprayed onto the bottom of the MD-disc is distributed to the walls of the bowl. This washes away loose debris, making cleaning easier.

Bowl flush for fast and easy cleaning

-

Transparent cover for safe work environment

An optional transparent cover is available to enclose the entire preparation area. When alcohol-based consumables are used, all the fumes are contained within the cover. The cover can also be connected to an exhaust so that all fumes are removed, making a safer working environment for operators.

Transparent cover for safe work environment

-

MD disc with cone for fast bowl liner change

The easy-to-remove MD disc allows for a fast change of bowl liner. It also has a higher mass than traditional MD discs, so it keeps the temperature of the preparation surface lower and can easily be cooled down using the disc cooling function.

MD disc with cone for fast bowl liner change

-

Removable bowl liner for fast cleaning

Tegramin’s bowl liner fits precisely into the bowl and collects all debris that is not washed down the drain. When the machine has to be cleaned, the bowl liner can easily be removed. It can then either be cleaned or discarded.

Removable bowl liner for fast cleaning

-

LED light for easier operation

The LED light illuminates the entire preparation area and makes it easy to follow the preparation process. When not used for 10 minutes, the Tegramin will enter standby mode, which saves electricity and reduces energy consumption.

LED light for easier operation

-

Emergency stop for greater safety

The emergency stop button immediately stops all moving parts.It is placed so it is easy to reach when working with the machine.

Emergency stop for greater safety

-

Recirculation cooling system for cost-efficient water use

Cooling water minimizes heat when grinding. One of Struers' recirculation cooling systems can be connected to Tegramin. This ensures cost-efficient water utilization and collects removed abrasives – to lower your water consumption and reduce the amount of classified products spent.

The recirculation cooling unit is especially useful to avoid blocking of the draining system in the lab and improves your environmental performance by ensuring waste and debris is collected in the filters and not washed down the drain. It is also very useful when there is no water connection nearby.Recirculation cooling system for cost-efficient water use

-

Easy operation with multifunction (turn/push) knob

Tegramin is designed with a large color display for easy operation. Navigation within the software is simple and it is very easy to change parameters using the turn/push knob.

Easy operation with multifunction (turn/push) knob

-

Material removal sensor for shorter grinding time

Tegramin’s built-in removal sensor ensures the shortest possible grinding time and saves you time on subsequent fine grinding or polishing steps.

When using time to measure material removal, there is a risk of too much material being removed, especially when working with multiple samples. Measuring material removal instead will ensure you only remove the material required, saving you time in the next process step.

Tegramin’s material measurement can be set to between 50 - 5,000 μm. This ensures only the necessary amount of material is removed – and guarantees the shortest possible grinding time.Material removal sensor for shorter grinding time

-

Automatic specimen mover plate lock increases accuracy

When the specimen mover plate has been moved into the correct position over the preparation surface, the coupling can be locked inside the specimen mover using a single screw. This eliminates any small movements in the specimen mover plate, resulting in significantly improved sample planeness.

Automatic specimen mover plate lock increases accuracy

-

Prepare single specimens or several specimens in a holder

To increase process flexibility, Tegramin can be used to prepare single or multiple specimens.

• Prepare a single specimen or an uneven number of specimens with a specimen mover plate. This is faster as you simply have to place the specimens on the preparation surface.

• Prepare multiple specimens by clamping them in a specimen holder. This is ideal when working with multiple specimens, even if they are of different shapes and sizes.Prepare single specimens or several specimens in a holder

Facts

Model types

Tegramin is available in three variations, see specifications for details.

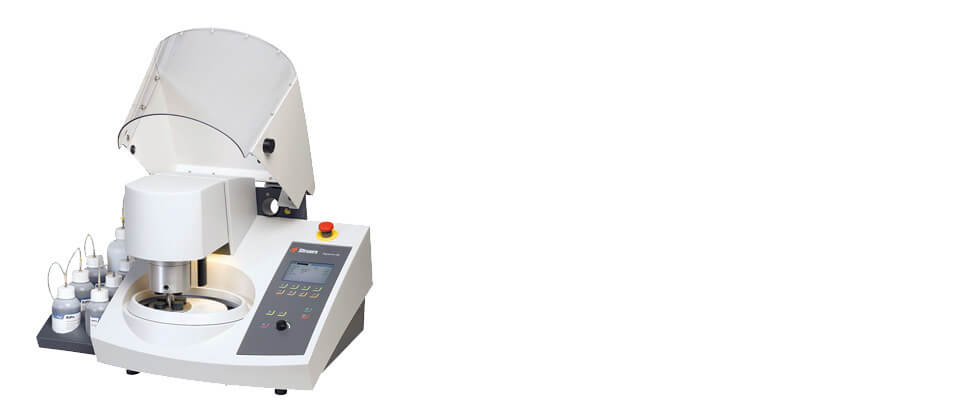

Tegramin-20

Automatic, microprocessor-controlled machine for grinding and polishing of specimens on a 200 mm MD-Disk with a cone. Dosing modules, an MD-Disk with a cone, and specimen holders are ordered separately. Tegramin-20 can be ordered with or without a transparent cover.

Tegramin-25

Automatic, microprocessor-controlled machine for grinding and polishing of specimens on a 250 mm MD-Disk with a cone. Dosing modules, a MD-Disk with a cone, and specimen holders are ordered separately. Tegramin-25 can be ordered with or without a transparent cover.

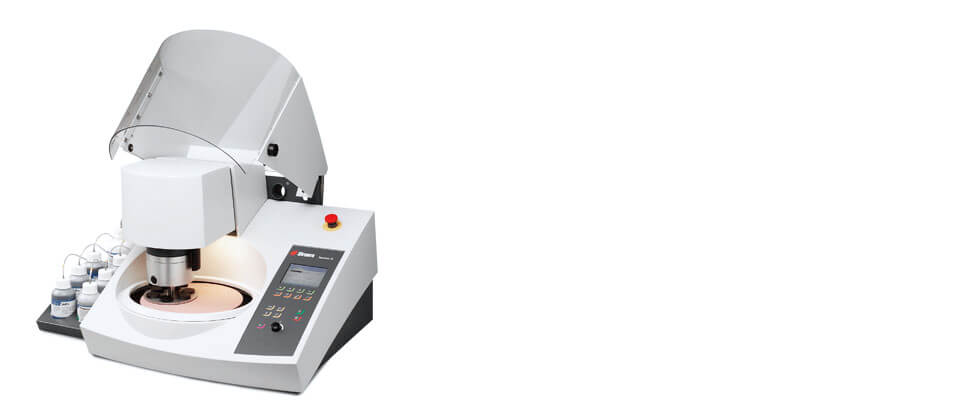

Tegramin-30

Automatic, microprocessor-controlled machine for grinding and polishing of specimens on a 300 mm MD-Disk with a cone. Dosing modules, an MD-Disk with a cone, and specimen holders are ordered separately. Tegramin-30 can be ordered with or without a transparent cover.

Struers’ equipment is in conformity with the provisions of the applicable international directives and their appurtenant standards.

Struers’ products are subject to constant product development. Therefore, we reserve the right to introduce changes to our products without notice.

Technical Data

Tegramin-20/-25/-30 Technical Data Sheet

Struers Technical Data Sheets are designed to help you make the best choice of equipment for your particular purpose. You can find important information such as capacity and performance specifications, dimensions, weight, electrical data, noise levels, ambient conditions, and safety. In many cases you can also obtain an overview of accessories offering higher capacity and performance.

Download Technical Data SheetPerfectly reproducible

Download our Tegramin brochure to get a full overview of this grinding and polishing equipment.

Download the brochureFind the right accessories for your Tegramin

Increase the efficiency of your process and improve the reliability of your result with our grinding and polishing accessories. We offer a full range of specimen holders, mover plates, leveling devices, and preparation discs.

Download our accessories overview sheetGrinding & Polishing consumables

-

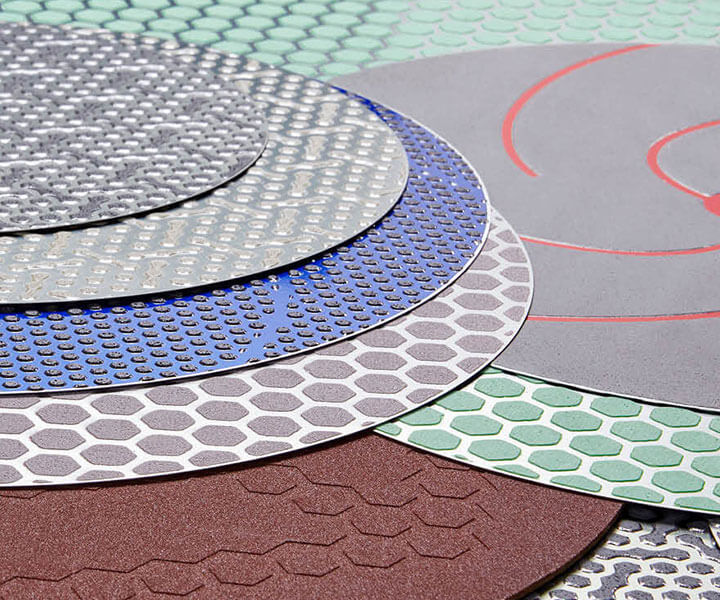

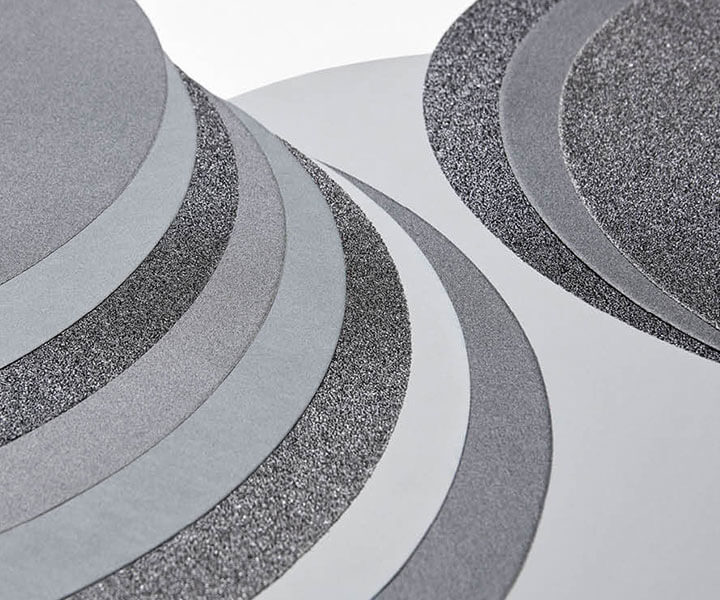

MD Grinding

For plane and fine grinding with virtually no artifacts

Read more Contact sales -

Silicon Carbide Foil and Paper

For plane and fine grinding

Read more Contact sales -

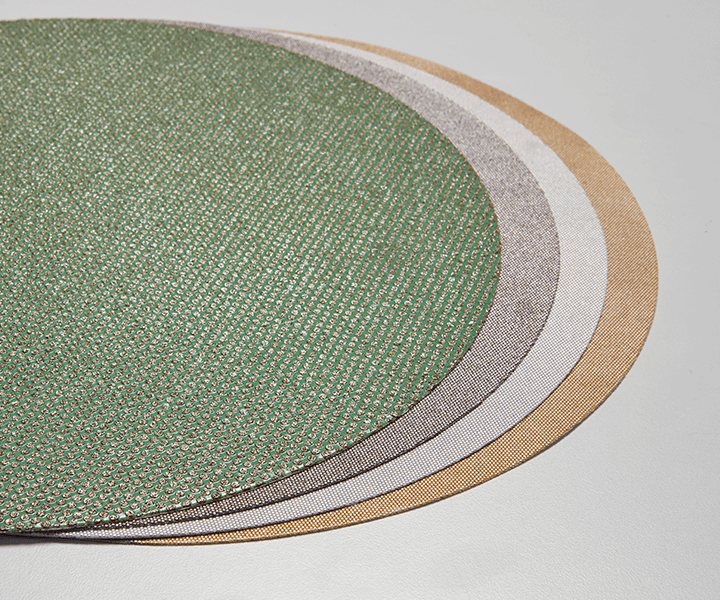

Diamond Pads

For plane and fine grinding of very hard materials

Read more Contact sales -

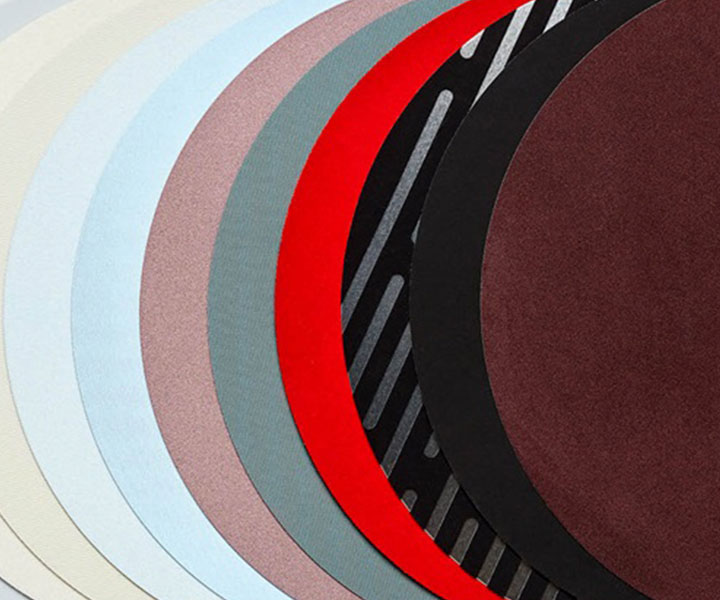

Polishing cloths

For any material and preparation goal

Read more Contact sales -

DiaPro

All-in-one diamond solution optimized for a specific polishing cloth

Read more Contact sales -

DiaDuo-2

All-in-one diamond solution

Read more Contact sales -

DP-Products

Diamond suspensions in a wide variety of grain sizes and formats

Read more Contact sales -

DP-Lubricants

For accurate cooling and lubrication while polishing

Read more Contact sales -

Oxide Polishing

When no scratches and deformation is required

Read more Contact sales -

+

-

−

Correct preparation solutions

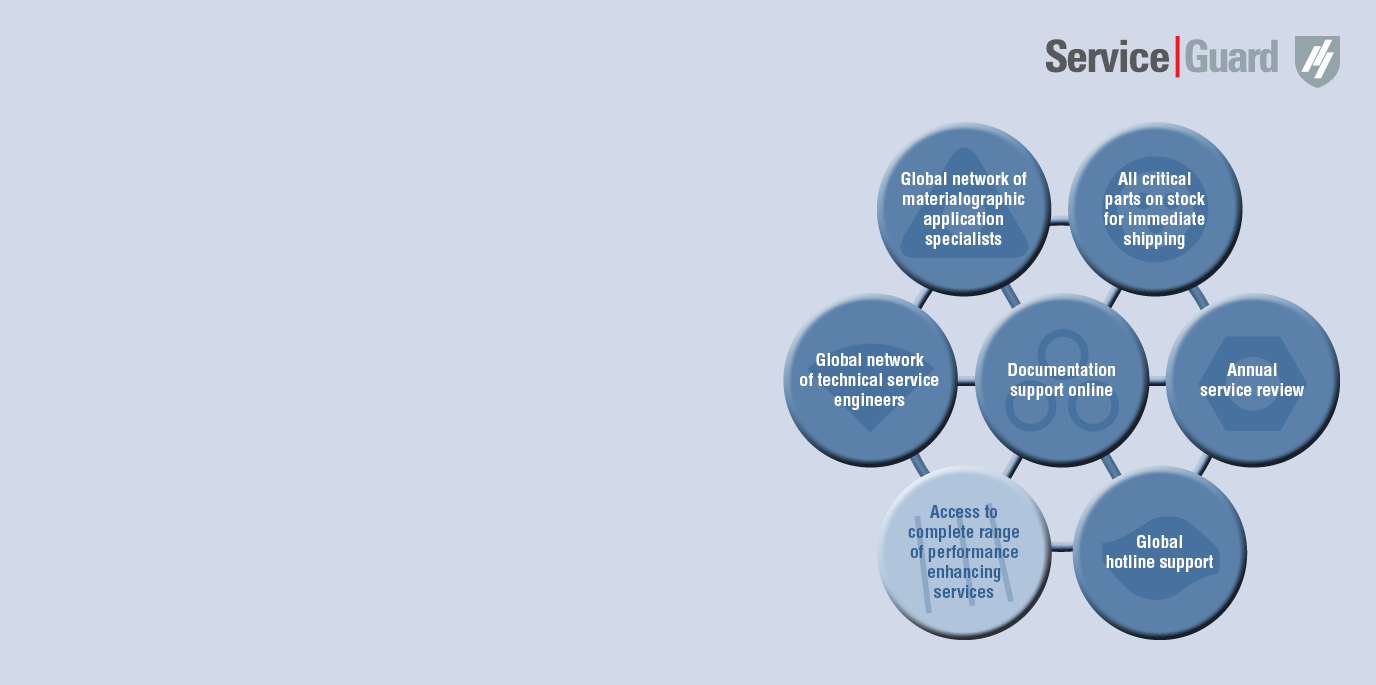

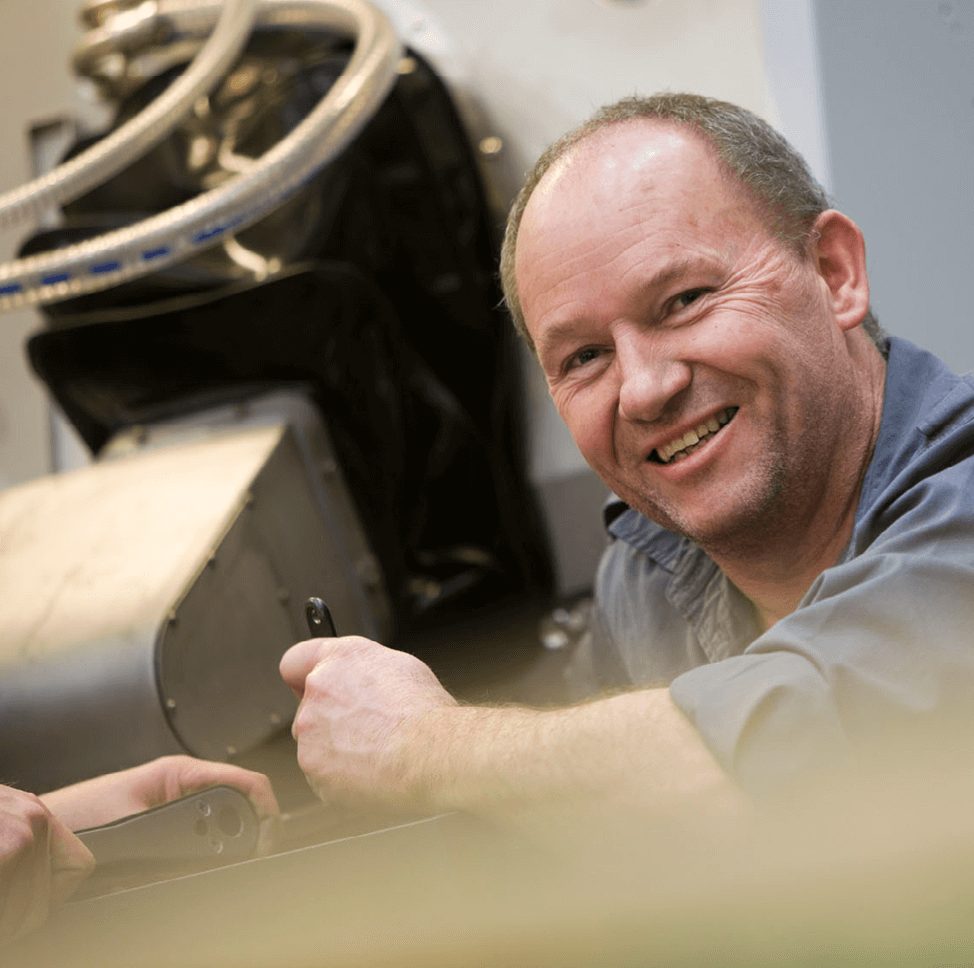

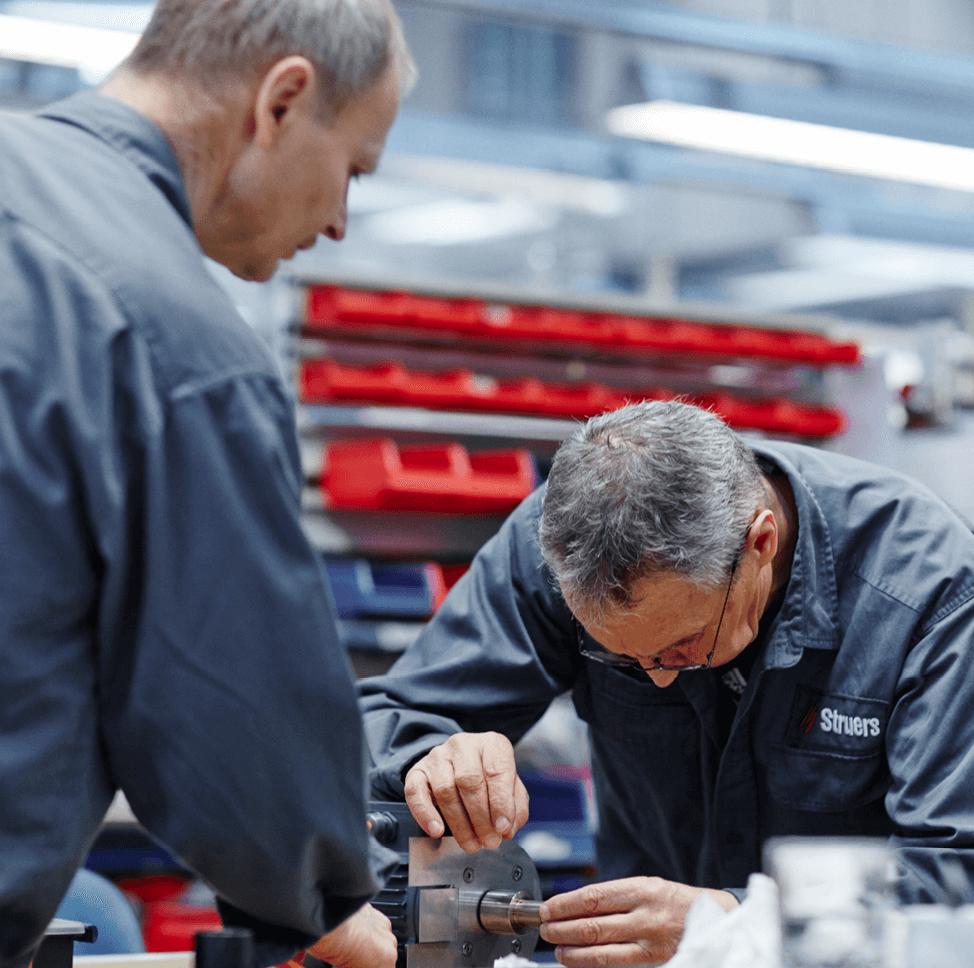

"True structures require proper and correct applications. Different material properties require broad application knowledge. Struers application specialists are experts in optimizing preparation methods, because application knowledge is necessary to select the correct preparation solutions. Your material – our application solutions.”

Birgitte Nielsen

Application Specialist, Struers ApS

References

My relationship with Struers dates back over many years. The reason is their expert advice, good service, and their use of our application laboratory in the case of difficult questions that are best resolved on-site.WWU Münster, Institut für Planetologie Ursula Heitmann Mineral Specimen Preparer

The Tegramin-25 and CitoPress-20 mean considerably easier and shorter workflows in the lab, and can be recommended.Stahlhärterei Haupt GmbH: Arkadiusz Bytner Labor and Quality Management Officer

“Struers Tegramin-30 enables us to achieve specimens free of scratches for improved evaluation, and saves us time and labor when compared to our former manual preparation with aluminum oxide.”Federal-Mogul Powertrain Mark Gibbins Materials Tester in Metal Technology