We are extremely satisfied with the highly skilled service delivered by Struers. They always meet our needs quickly and efficiently.BRP Powertrain GmbH & Co. KG (Austria) Herr Thomas Brunmair Supervisor Material Lab

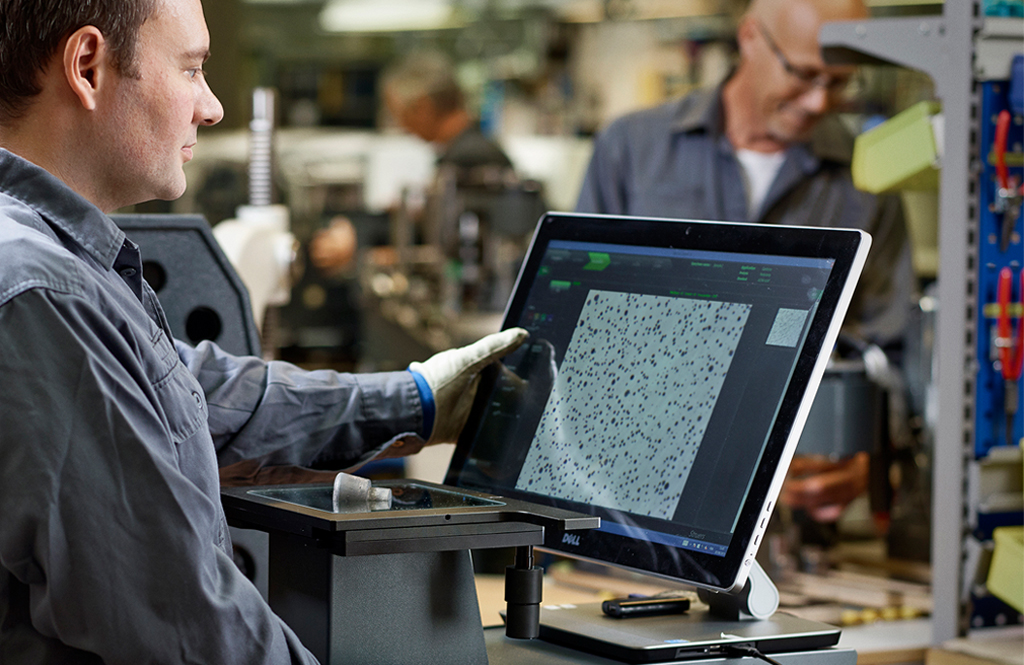

Designed for both the production and lab environments, StructureExpert is an all-in-one solution dedicated to a particular application. Challenging conventional technology, StructureExpert does away with conventional and time-consuming positioning and adjustments, enabling reliable verification of a specimen within 30 seconds and delivering critical quality control data in line with the production line.

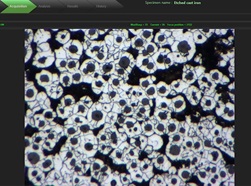

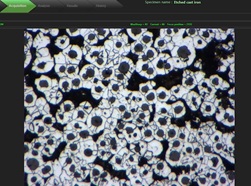

The user can verify a prepared specimen in just 30 seconds, based on a magnified, crystal clear and high-resolution digital image. Save even more time by locating the StructureExpert close to your QC function – if necessary, right beside the production line.

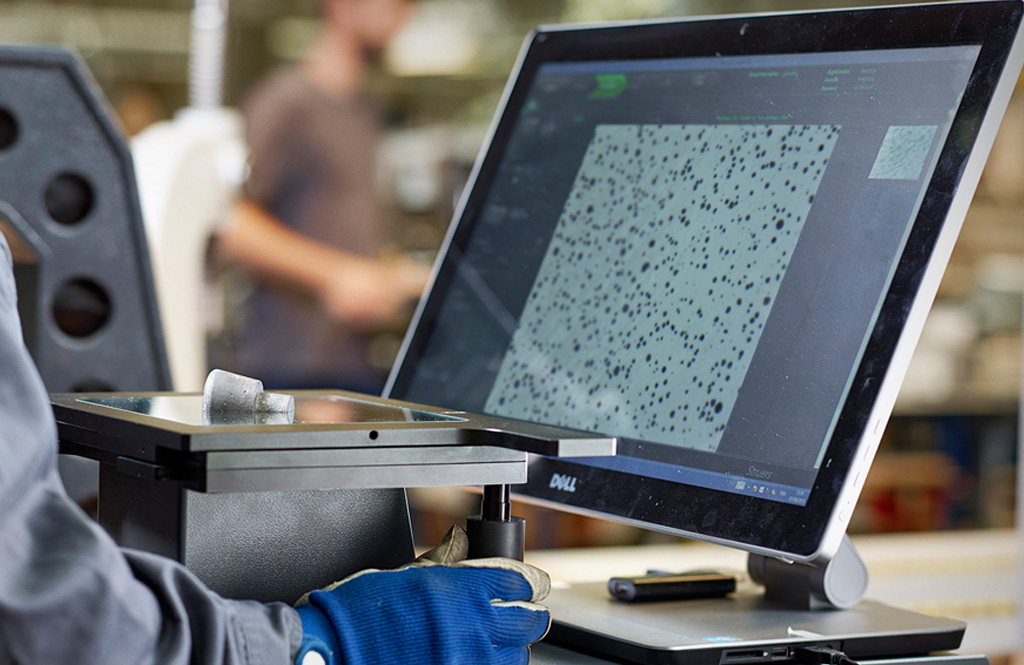

StructureExpert can be used in virtually any production environment. The optical equipment is completely protected by a robust and dustproof housing, allowing you to save time by performing verifications right where they are needed.

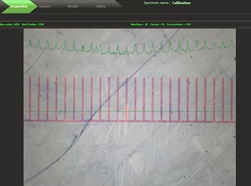

A straightforward user interface and an automated step-by-step process mean rapid familiarization and consistent repeatability.

Dedicated software modules provide an intuitive workflow, enabling correct image acquisition without any special operator training.

The inverted optical system maintains a constant distance between the sample and the camera, providing a constantly sharp image without the need for continuous height adjustments and calibrations.

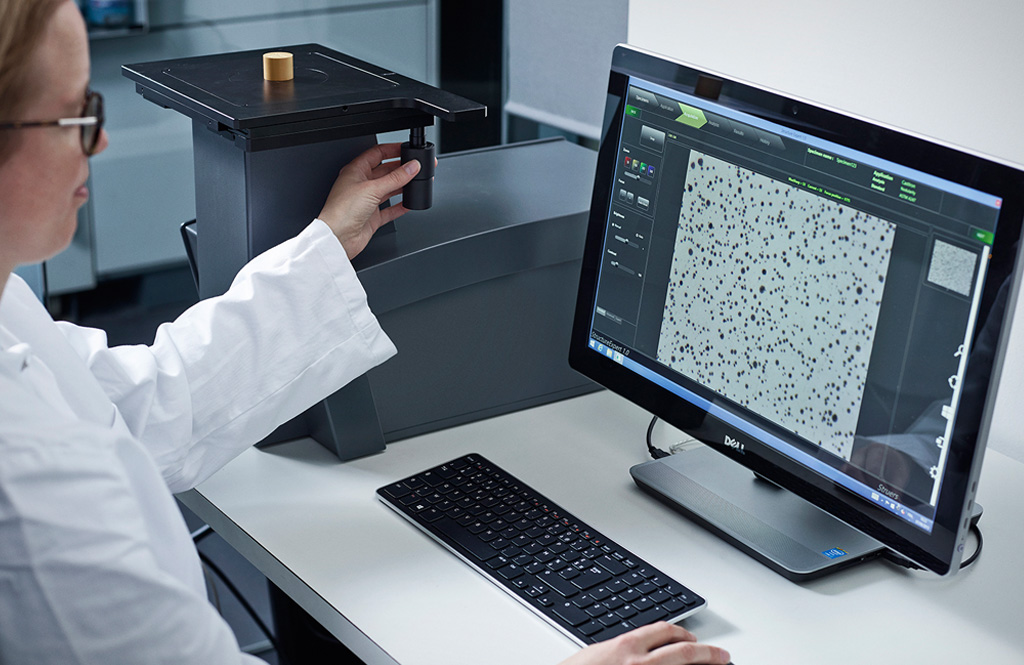

The built-in digital camera and a motorized autofocus zoom lens give maximum flexibility in selecting a perfect field of view.

Specimen illumination and contrast is automatically adjusted to ensure perfect conditions for the given application and the surface conditions detected by the system. This eliminates the need for tedious light and filter adjustments and significantly simplifies the analysis.

The zoom system offers the operator maximum flexibility in selecting a perfect field of view for all measurements without the need to select and switch between objective lenses. Automatic focus on the sample surface eliminates the need for manual adjustments. This means unmatched ease of use and optimized repeatability.

Contrary to conventional manual verification technology, the sample surface is always the same distance from the camera. This does away with time-consuming, continuous height adjustments and calibrations, thus significantly reducing operator time, while maximizing the image quality.

Struers’ equipment is in conformity with the provisions of the applicable international directives and their appurtenant standards.

Struers’ products are subject to constant product development. Therefore, we reserve the right to introduce changes to our products without notice.

Struers Technical Data Sheets are designed to help you make the best choice of equipment for your particular purpose. You can find important information such as capacity and performance specifications, dimensions, weight, electrical data, noise levels, ambient conditions, and safety. In many cases you can also obtain an overview of accessories offering higher capacity and performance.

Download Technical Data Sheet

"True structures require proper and correct applications. Different material properties require broad application knowledge. Struers application specialists are experts in optimizing preparation methods, because application knowledge is necessary to select the correct preparation solutions. Your material – our application solutions.”

Birgitte Nielsen

Application Specialist, Struers ApS

Don’t make do with what we say! Look for the truth in the experiences of the people who use our equipment and knowledge. We asked a few of our loyal customers to tell us what they think is most important about Struers.

We are extremely satisfied with the highly skilled service delivered by Struers. They always meet our needs quickly and efficiently.BRP Powertrain GmbH & Co. KG (Austria) Herr Thomas Brunmair Supervisor Material Lab

Since adopting Struers equipment, we have made significant savings within our manufacturing process as a result of reduced manpower requirements and productivity improvements.Nissan Motor Manufacturing UK Ltd. John Smart Production Supervisor

My relationship with Struers dates back over many years. The reason is their expert advice, good service, and their use of our application laboratory in the case of difficult questions that are best resolved on-site.WWU Münster, Institut für Planetologie Ursula Heitmann Mineral Specimen Preparer