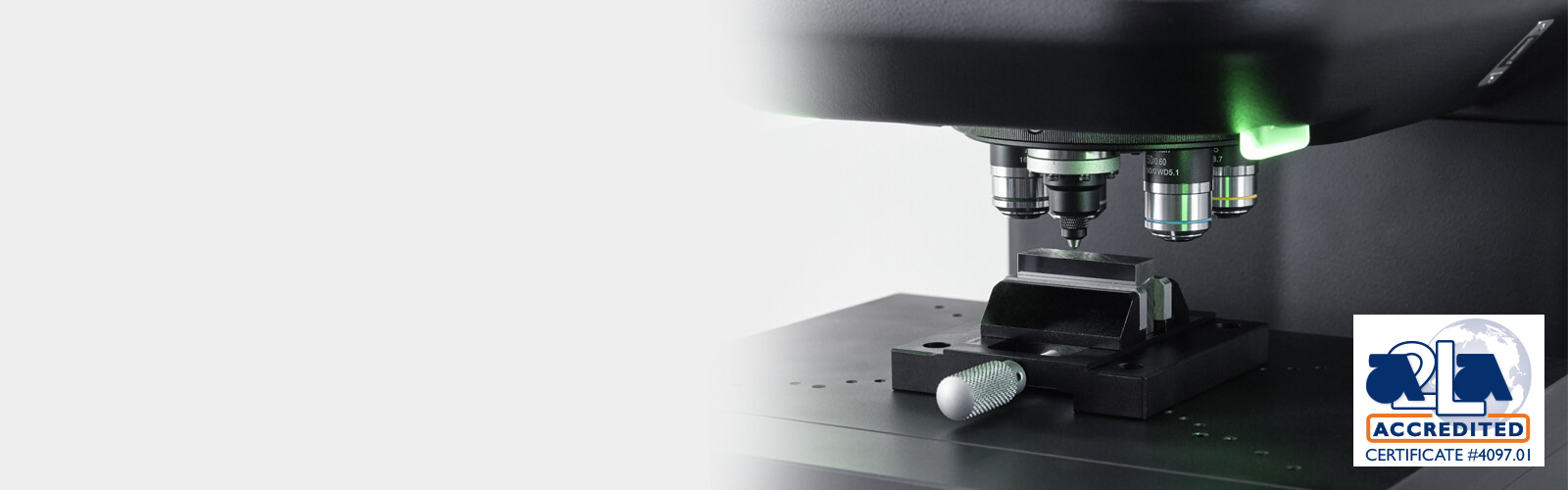

Struers is an A2LA Accredited ISO-17025 Calibration Lab

Struers has successfully completed the rigorous A2LA certification program and are proud to offer fully accredited ISO-17025 calibrations in accordance with both ASTM and ISO specifications for hardness testers.

We are able to perform both Direct and Indirect Verifications on all of the hardness testers Struers sells and Indirect Verifications of non-Struers machines.

Contact us