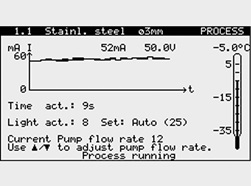

Fast determination of method settings

TenuPol-5 is equipped with a unique scanning function that scans a pre-defined voltage range to determine the current density curve. This curve is used to define the correct polishing voltage for the thinning process, allowing the user to store the parameters in order to find the correct method settings again after a single scan of a new material sample. The TenuPol-5 comes with filter and enhance functions to facilitate finding the correct voltage settings for polishing and etching.

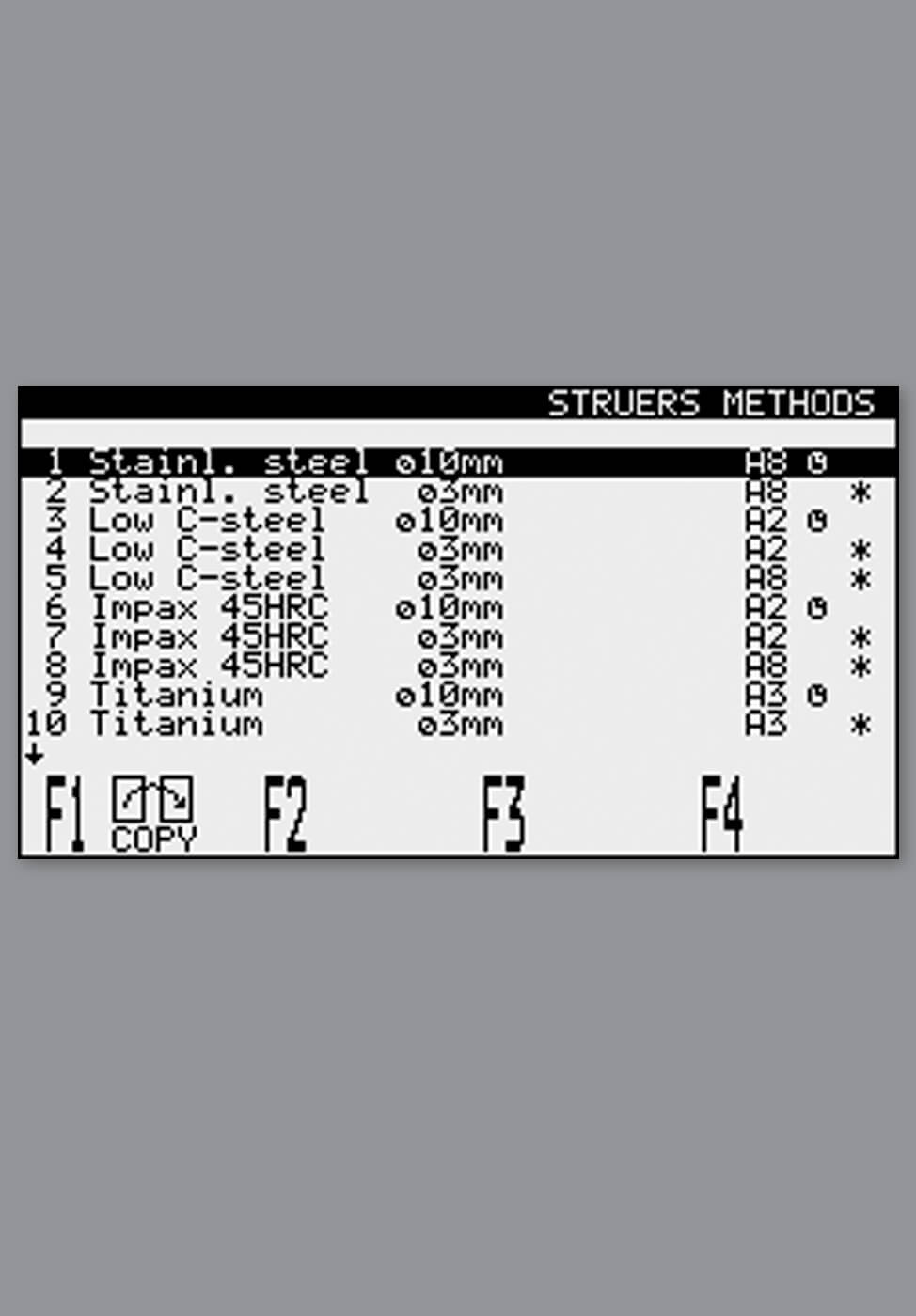

Comprehensive method database

The built-in method database contains 18 Struers methods and up to 200 user methods. The 18 methods consist of eight methods for pre-thinning and ten methods for the final thinning of various materials. This means that the user can prepare a wide range of materials immediately without time-consuming trials. The user can also use the methods in the database as a starting point for developing their own methods for other materials.

High specimen quality

The specimen is polished from both sides simultaneously, thus providing a structure with an absolute minimum of deformation. When the perforation appears, the polishing can automatically be stopped by the infrared detector system, and the specimen is ready for TEM examination. No special operator training is required.