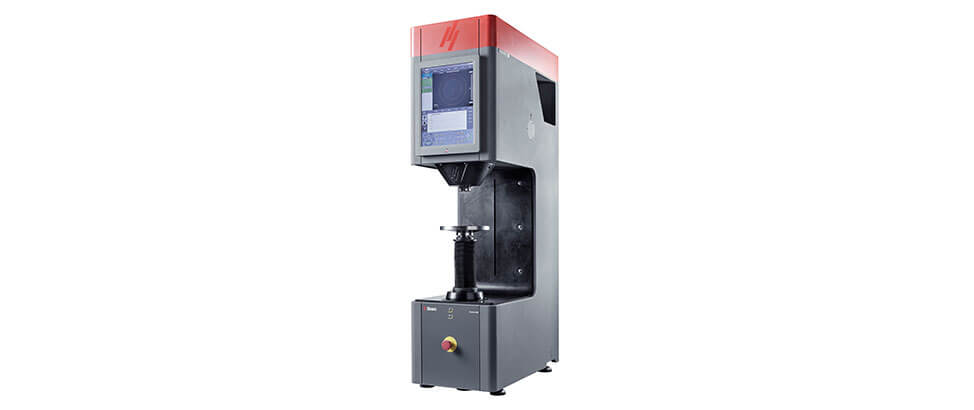

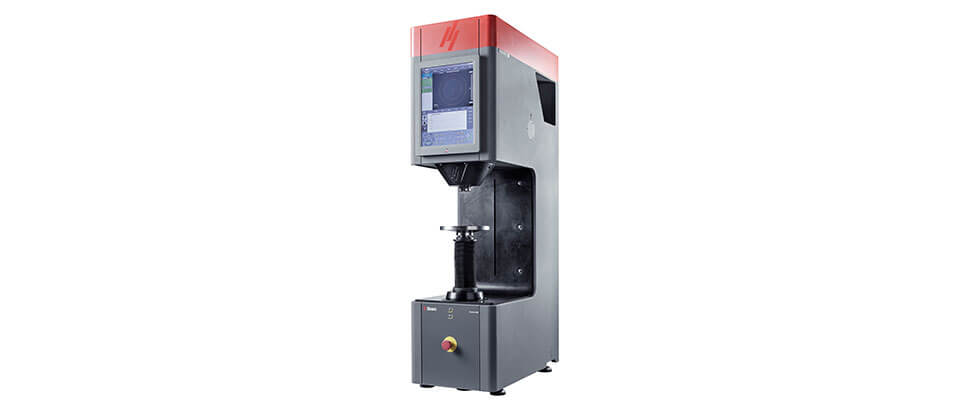

Model Types

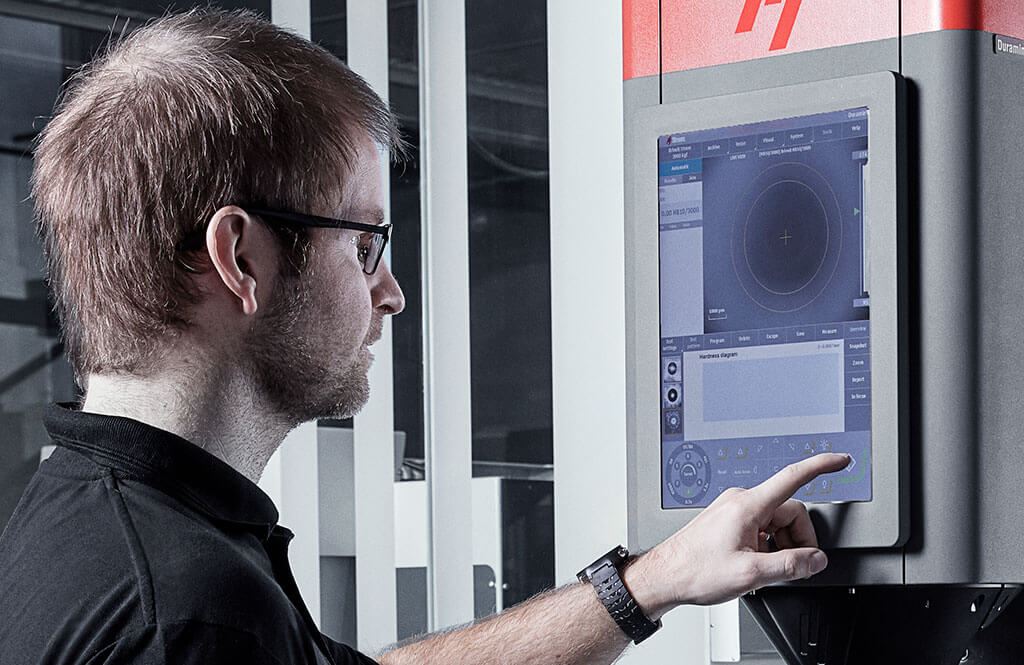

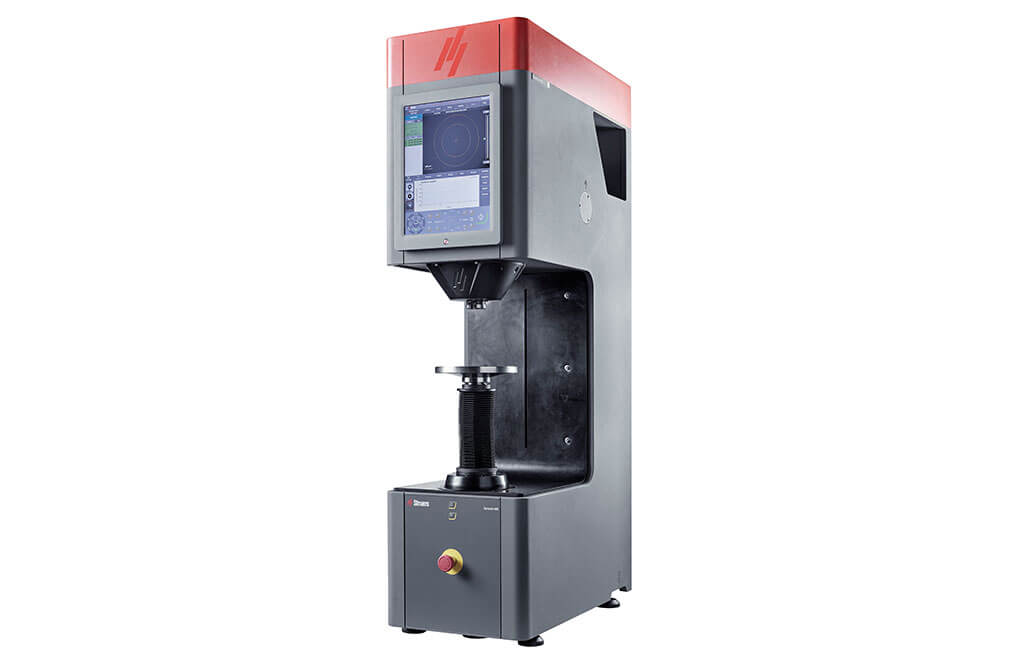

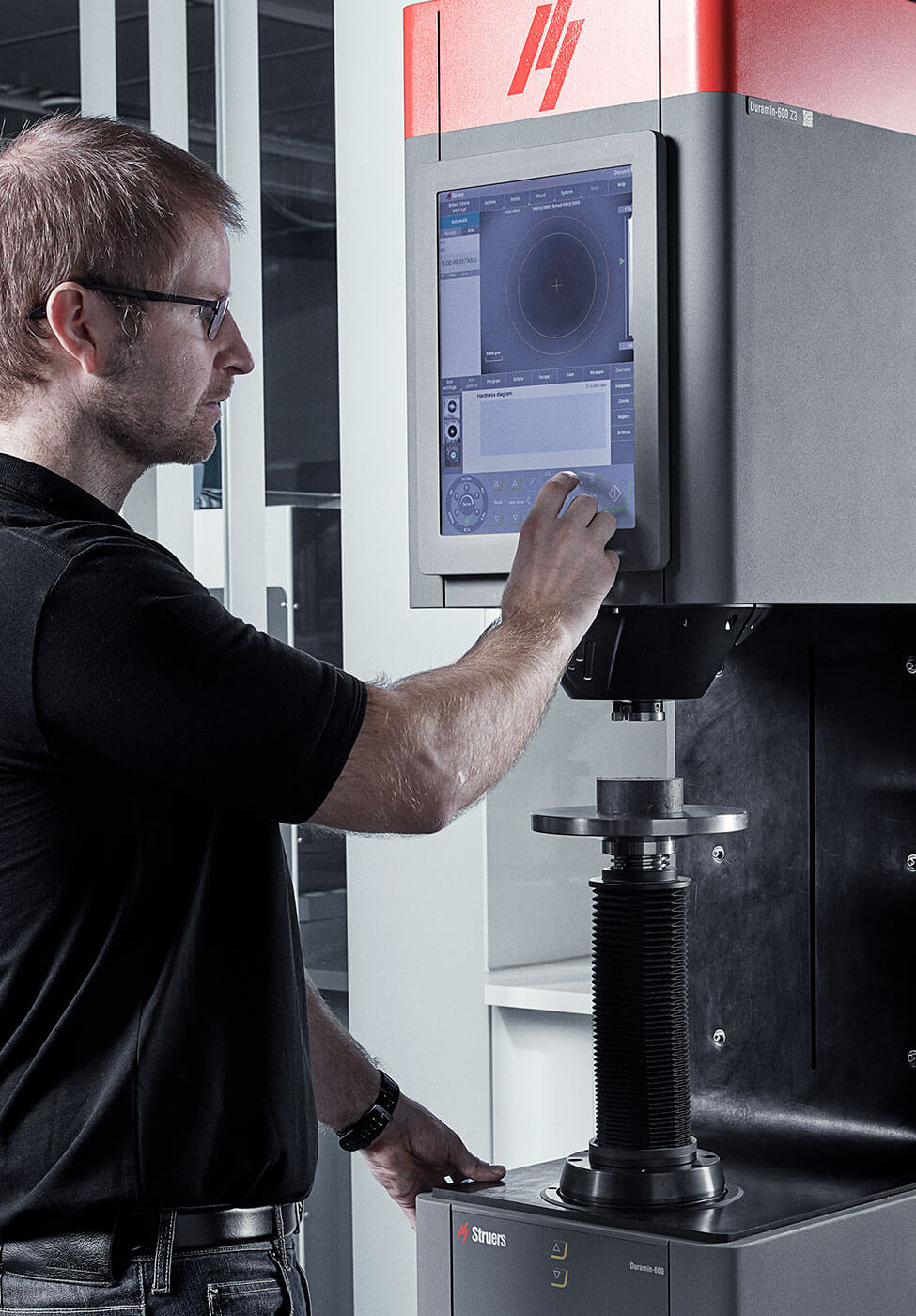

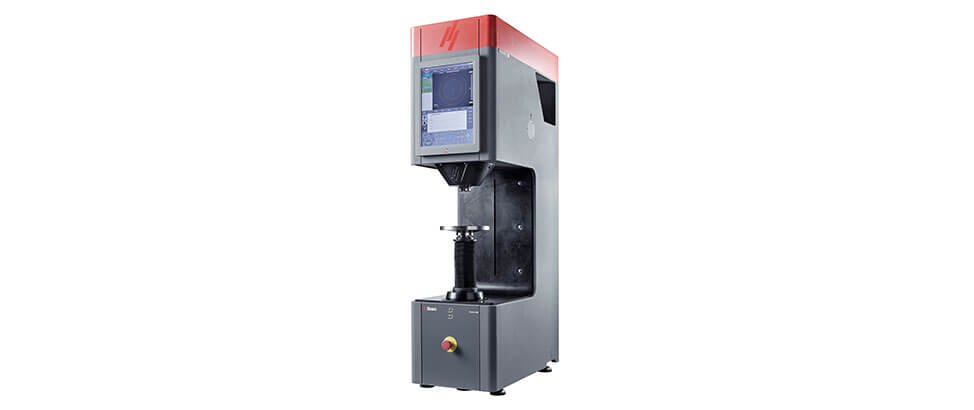

The Duramin-600 models come with a motorized, six-position turret, automatic illumination adjustment, auto focus, and automatic image evaluation as standard. The maximum sample height is 330 mm, with a throat depth of 260 mm. Duramin-600 is operated via a 15-inch color touchscreen. Objective lenses and indenters are ordered separately. All Duramin-600 M models come with manual Z-axis adjustment. All Duramin-600 Z models come with a motorized Z-axis adjustment.

Duramin-600 M1

Universal hardness tester with load cell technology for the automatic hardness testing of Brinell, Vickers, Rockwell, and Knoop With an extended load range of 9.8 N to 2450 N (1-250 kgf).

Duramin-600 M2

Universal hardness tester with load cell technology for the automatic hardness testing of Brinell, Vickers, Rockwell, and Knoop With an extended load range of 29.4 N to 7,360 N (3.0-750 kgf)

Duramin-600 M3

Universal hardness tester with load cell technology for the automatic hardness testing of Brinell, Vickers, Rockwell, and Knoop With an extended load range of 49.1 N to 29,430 N (5.0-3,000 kgf)

Duramin-600 Z1

Universal hardness tester with load cell technology for the automatic hardness testing of Brinell, Vickers, Rockwell, and Knoop With an extended load range of 9.8 N to 2450 N (1-250 kgf).

Duramin-600 Z2

Universal hardness tester with load cell technology for the automatic hardness testing of Brinell, Vickers, Rockwell, and Knoop With an extended load range of 29.4 N to 7,360 N (3.0-750 kgf)

Duramin-600 Z3

Universal hardness tester with load cell technology for the automatic hardness testing of Brinell, Vickers, Rockwell, and Knoop With an extended load range of 49.1 N to 29,430 N (5.0-3,000 kgf)

Struers’ equipment is in conformity with the provisions of the applicable international directives and their appurtenant standards. Struers’ products are subject to constant product development. Therefore, we reserve the right to introduce changes to our products without notice.