COMPLETE SOLUTIONS

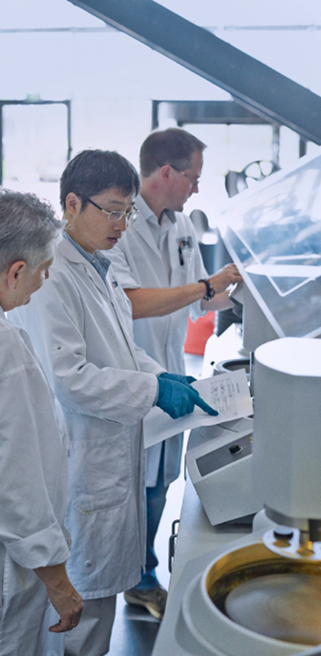

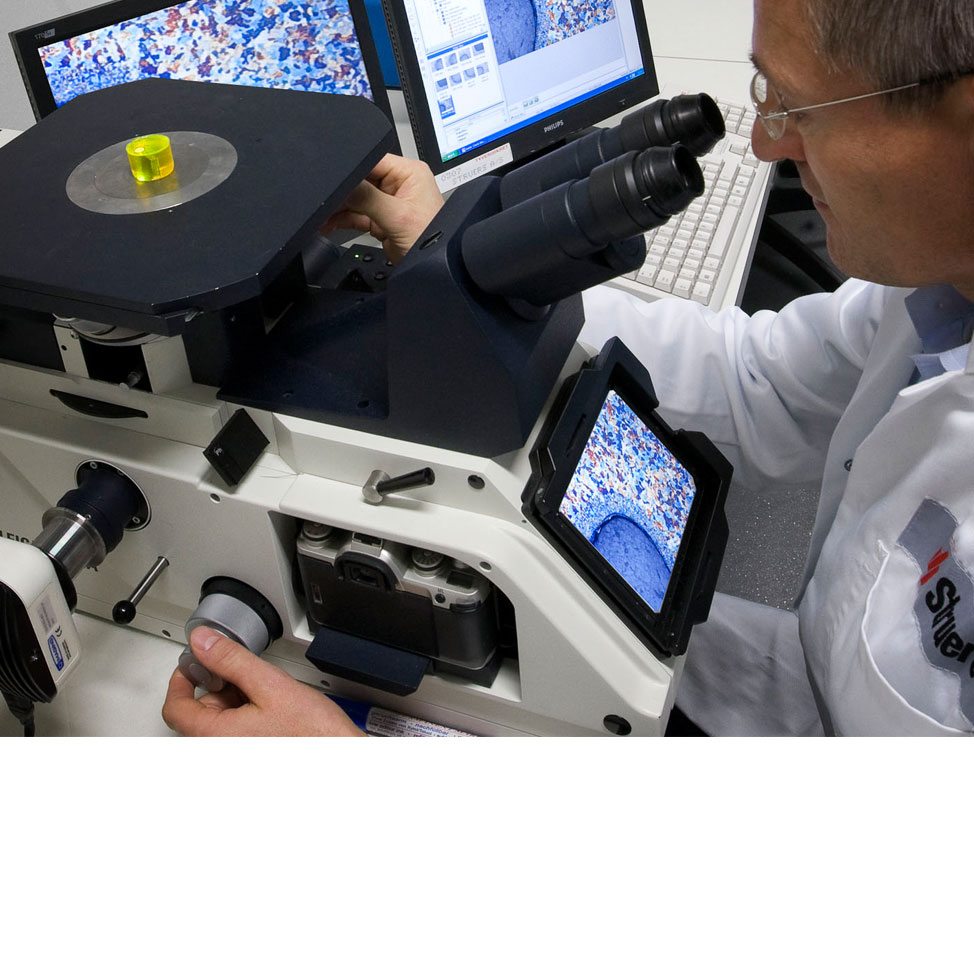

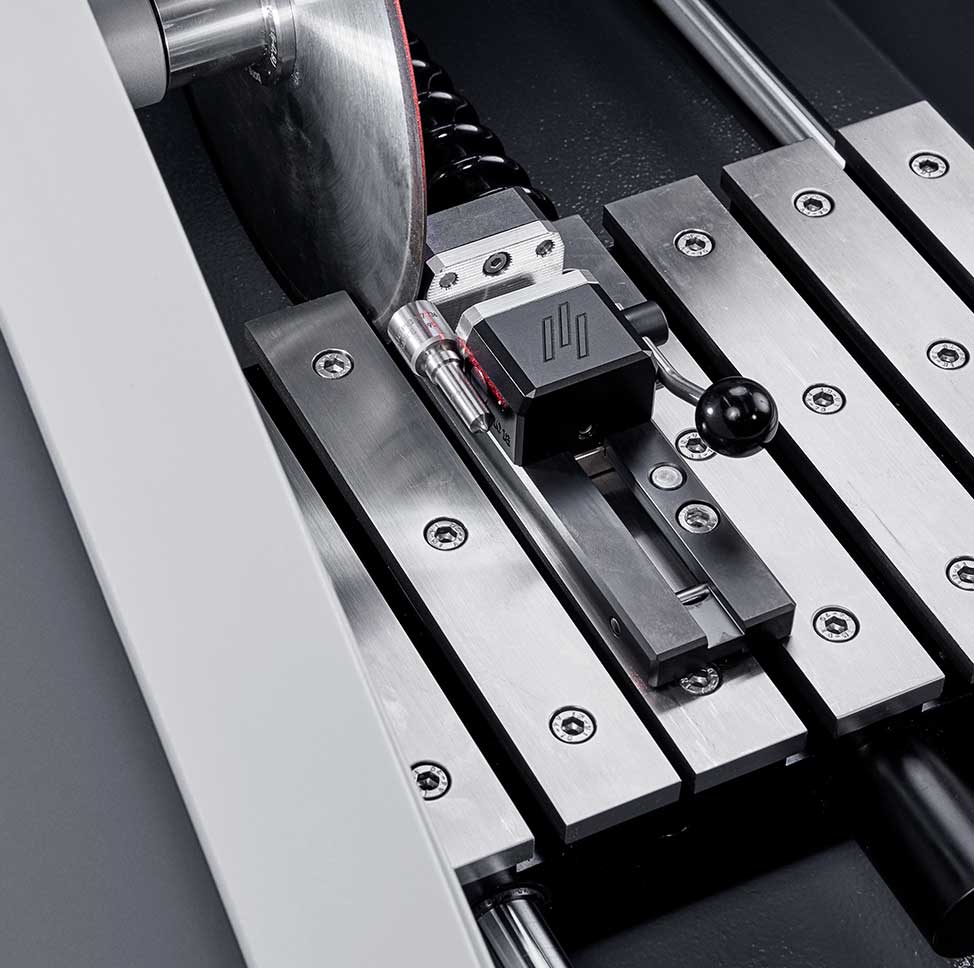

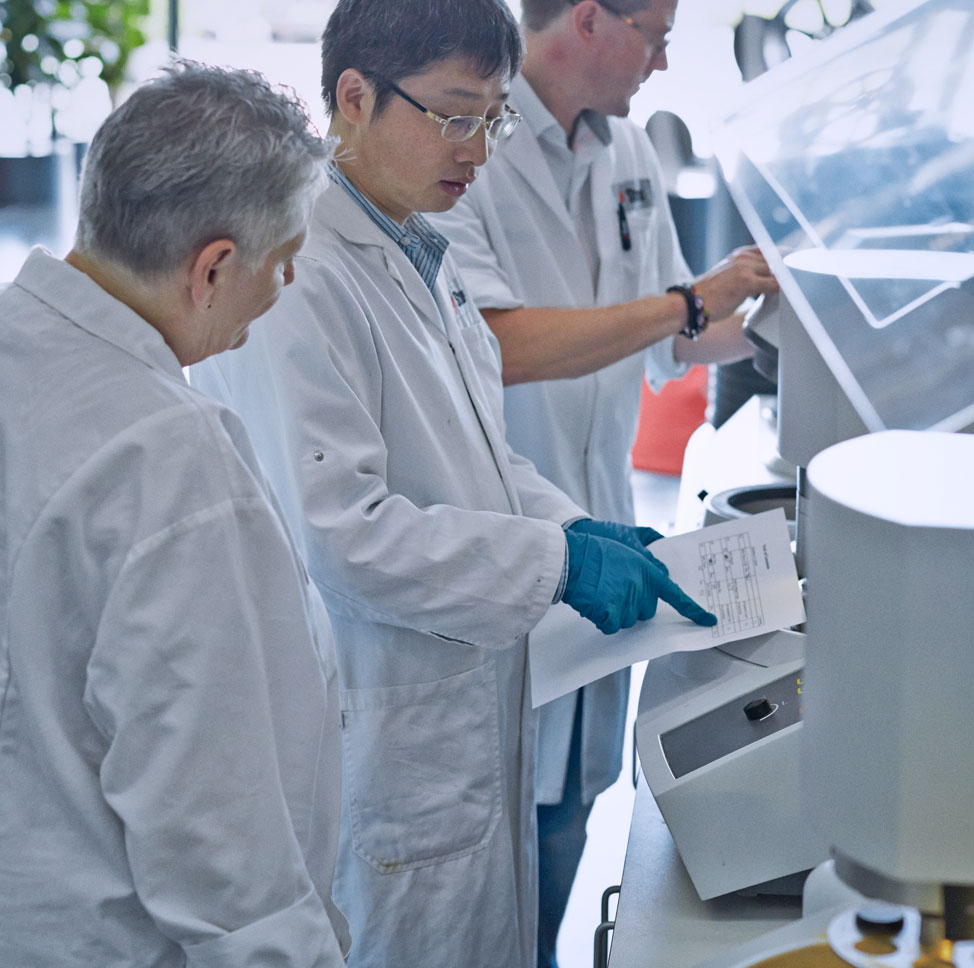

New applications are emerging with new advanced materials such as composites, lightweight alloys, miniature electronics and mechanics, as well as high-performance ceramics, polymers, and metals.

Things are also moving faster with short delivery times for products and quality documentation. More and more manufacturers need fast changeovers between many different products, meaning short running in times, and optimum capacity exploitation. Quality demands require smaller tolerances, while manufacturers are experiencing higher personnel turnover and a lack of qualified operatives.