BIENVENIDOS A LA ACADEMIA STRUERS

Creemos en el uso compartido de conocimientos. El conocimiento que adquiere hoy debería poder aplicarlo mañana en su laboratorio, desde la preparación hasta el examen de materiales y el mantenimiento de equipos.

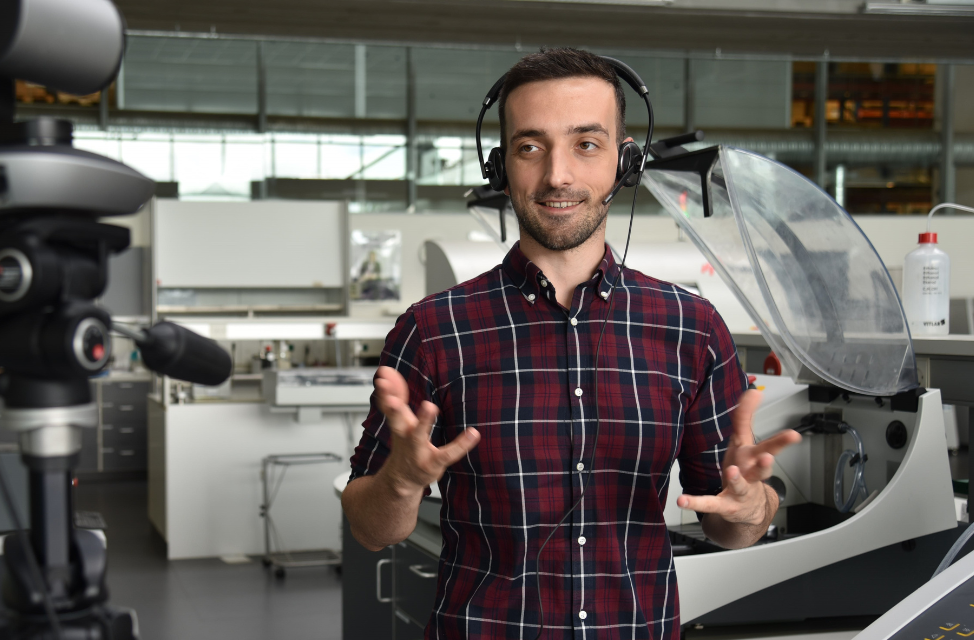

En la academia Struers ofrecemos formación metalográfica y seminarios web en respuesta a todas sus necesidades. Puede participar en una sesión de formación individual, en un curso adaptado a sus necesidades o en uno de nuestros populares seminarios web online para mejorar sus conocimientos sobre la preparación gráfica de materiales.

Ver el calendario de formación y seminarios web