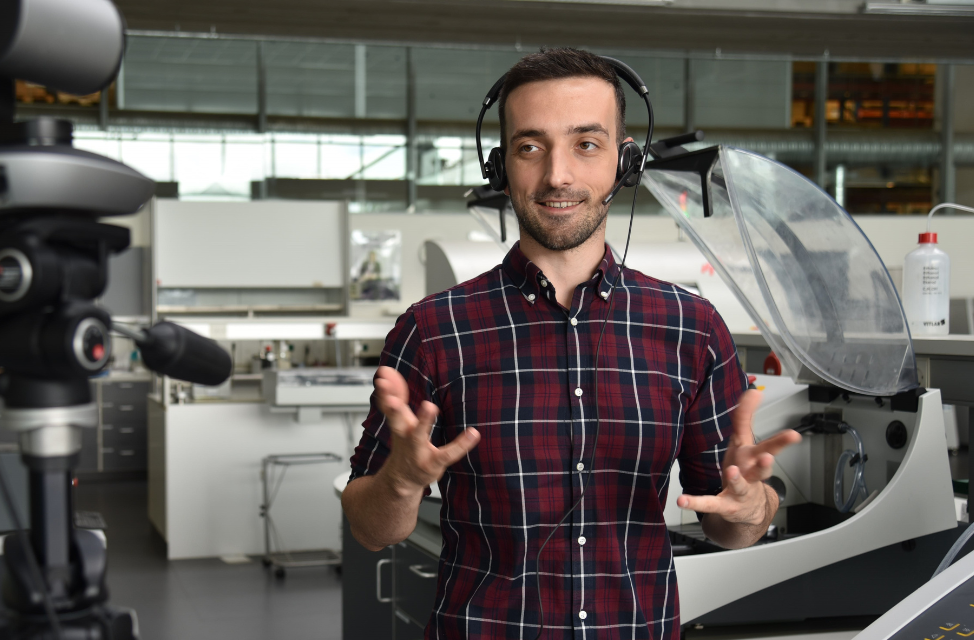

BIENVENUE DANS LA STRUERS ACADÉMIE

Nous croyons au partage des connaissances. Ce que vous apprenez aujourd’hui doit être appliqué demain dans votre laboratoire, de la préparation à l’examen des matériaux et à l’entretien des équipements.

À la Struers Académie, nous proposons une formation et des webinaires sur la métallographie pour répondre à tous vos besoins. Vous pouvez participer à une session de formation individuelle, suivre un cours adapté à vos besoins ou participer à l’un de nos webinaires en ligne tant appréciés pour améliorer vos connaissances en matière de préparation graphique des matériaux.

Voir l'agenda des formations et des webinaires