Recorded Webinar

Method and Equipment Demo - Hardness Testing

Join us live as we demonstrate Struers’ solutions for Hardness Testing!

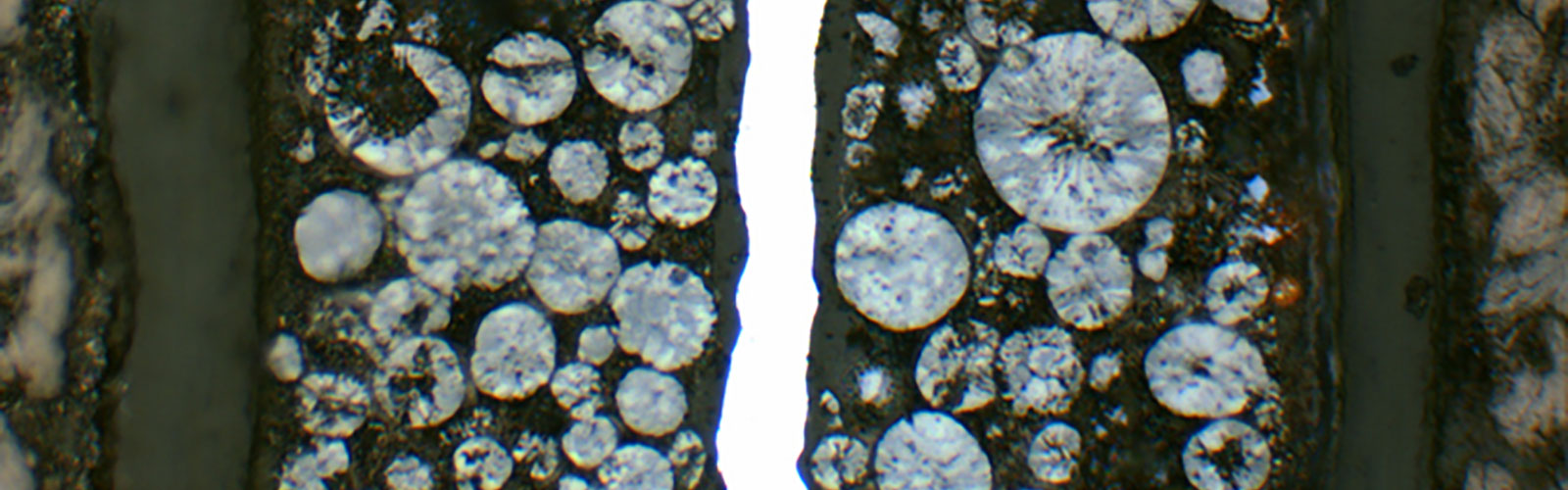

Material hardness is quantified through the process of applying a known force with a hard diamond or WC indenter tip into a sample material for a set amount of time. This creates a relatively small indent on the sample surface, and is considered a form of non-destructive testing. By measuring how the indenter interacts with the sample a hardness value is calculated, and one can be sure that the material being produced will adhere to quality and safety standards. To calculate a hardness value, indents are either measured optically for size or the depth of the indenter into the sample surface is measured. Struers offers a wide range of hardness testers to accommodate different testing methods, throughputs, and sample sizes. Our automatic testers allow us to precisely measure vast areas of multiple samples to ensure components will conform to aerospace and automotive production requirements. Hardness testing gives us confidence that our forms of transportation are built with components that will not fail pre-maturely under normal working conditions.Join us live as we demonstrate:

-Specifications for all Struers hardness testing equipment options

-Knoop, Vickers, Brinell, and Rockwell hardness testing differences

-Manual and automatic hardness testing methods

-Contour scanning, hardness mapping, and additional hardness testing accessories