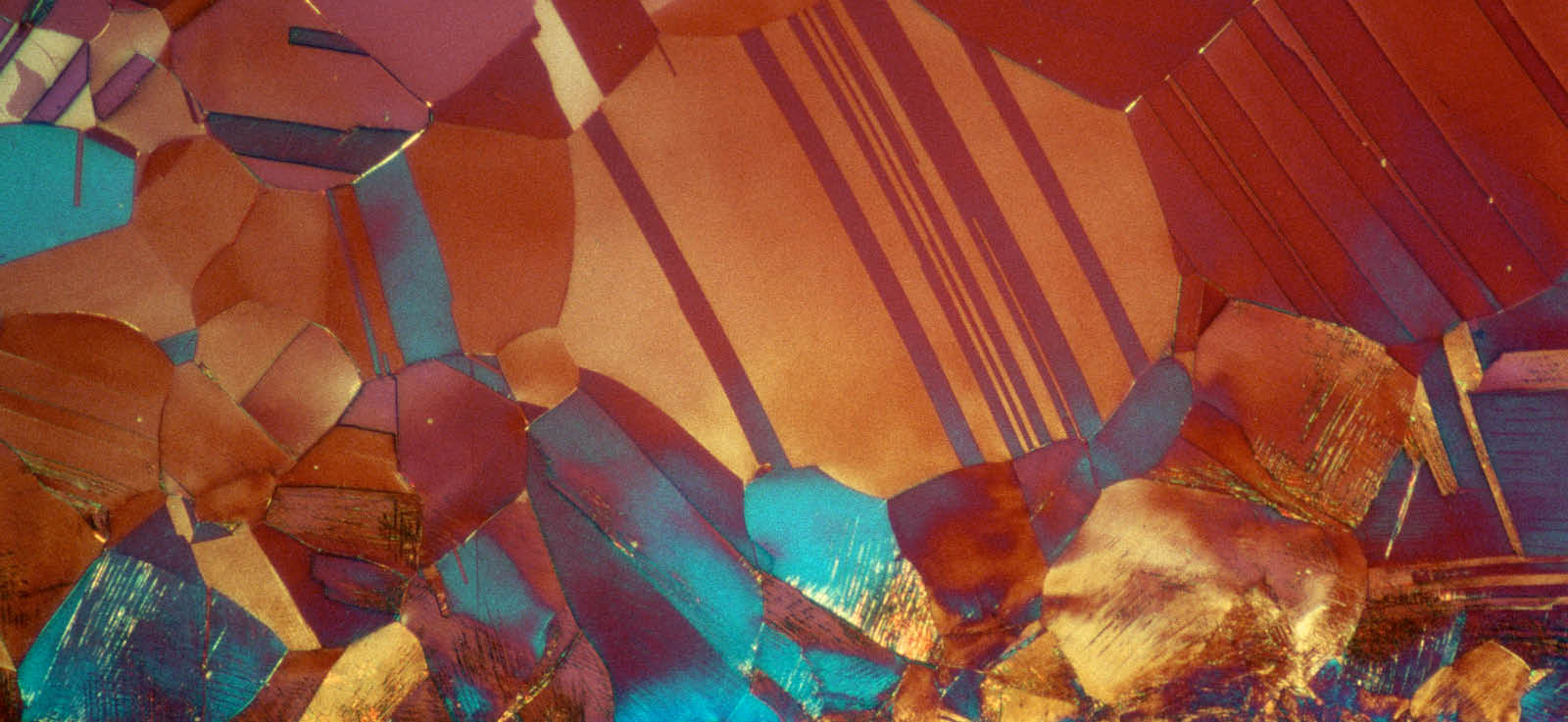

WIN A STRUERS STRUCTURE CALENDAR

Enter now for a chance to win the popular Struers Structure Wall Calendar 2026 for your lab. This stunning calendar features captivating metal and material structures, expertly prepared using Struers equipment, with contributions from professionals worldwide.

We will draw 20 lucky winners in December, and the winners will be directly informed.

YES, I WANT TO WIN

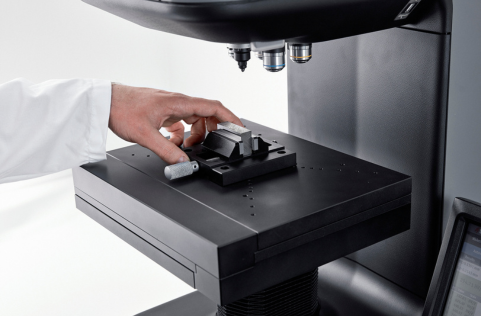

A full range for all needs

You can find the right equipment for every conceivable materialographic preparation need to make sure you achieve the quality, productivity, and cost efficiency you are looking for.

- Cutting equipment

- Mounting equipment

- Grinding and polishing equipment

- Hardness testers

- Image analysis equipment

- Customized equipment

See the full range of equipment

ONLINE SHOPPING FOR CONSUMABLES HAS NEVER BEEN EASIER

Original Struers consumables are designed to give you the best preparation results and protect your equipment. Save time by ordering original Struers consumables from your desktop in the Struers Webshop – at your convenience.Contact us

How to

You can make sure that you and your staff have the right knowledge at the right level for your operation by making use of Struers’ unique materialography knowledge base.

- Cutting guides

- Mounting guides

- Grinding and polishing guides

- Electrolytic preparation guides

- Hardness testing guides

- Etching guides

Find the “how to” guides you need

Global brands that place their trust in our equipment and services

We are proud of the strong partnerships that we have built with leading industrial brands, prestigious universities, and respected research establishments. They demand a supplier with global reach, world-class equipment, and in-depth knowledge that they can rely on.

Optimize your entire metallographic process with our most popular consumables

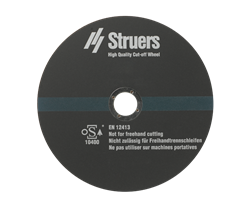

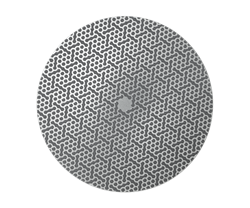

| Cut-off wheel | MD-Piano | DP-Spray | EpoFix Resin |

|

Catalog number 40009106

|

Catalog number 40800130

|

Catalog number 40600145

|

Catalog number 40200030

|

|

Product description: 10 pieces abrasive cut-off wheels with dimensions 250 x 1.5 x 32 mm for cutting of medium hard ferrous metals, stainless steel, and general applications. |

Product description: A resin bonded diamond surface, designed and developed for plane grinding and fine grinding of materials in the hardness range HV150-2000. |

Product description: A spray can exclusively containing polycrystalline diamonds for high performance. |

Product description: EpoFix is a slow-curing transparent epoxy, particularly suited for vacuum impregnation and mounting of very delicate specimens. It is to be mixed with EpoFix Hardener. |

| Buy in Webshop | Buy in Webshop | Buy in Webshop | Buy in Webshop |