WELCOME TO STRUERS ACADEMY

We believe in knowledge sharing. What you learn today should be applied tomorrow in your lab, from the preparation to the material examination and service of equipment.

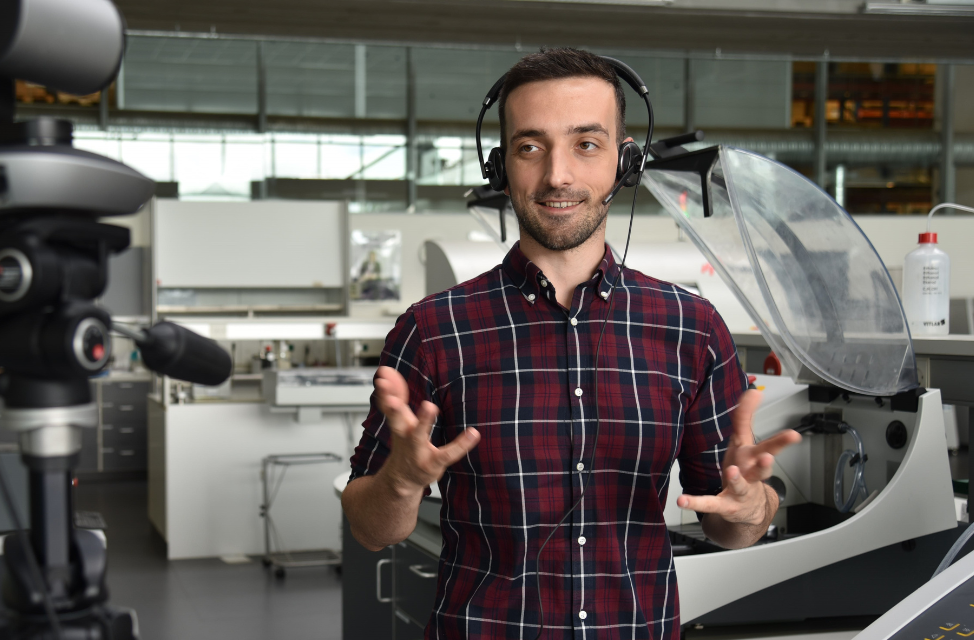

At Struers Academy, we offer metallographic training and webinars to tailor all your needs. You can participate in an individual training session, have a course tailored to your needs, or participate in one of our popular online webinars to improve your material graphic preparation knowledge.

See the training and webinar calendar